Engine Ventilation

VOL 29/NUMBER 2

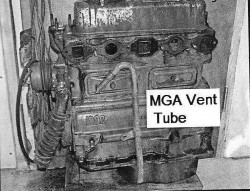

My 1969 MGB had some emission controls namely a smog pump and positive crankcase ventilation (PCV). I had long ago removed these items to make the engine more in the form of a 1967 or earlier engine. The PCV was an early form, with the crankcase vented by a hose from the engine side cover. That was divided by a Y-fitting to feed into each carburetor body where it attached to the intake manifold. I removed these hoses, plugged the carburetor bodies, and used the side cover and vertical vent tube from an MGA, as shown in Figure 1 (below).

My 1969 MGB had some emission controls namely a smog pump and positive crankcase ventilation (PCV). I had long ago removed these items to make the engine more in the form of a 1967 or earlier engine. The PCV was an early form, with the crankcase vented by a hose from the engine side cover. That was divided by a Y-fitting to feed into each carburetor body where it attached to the intake manifold. I removed these hoses, plugged the carburetor bodies, and used the side cover and vertical vent tube from an MGA, as shown in Figure 1 (below).

The reason I bring this up is that looking around the cars at GT28 and at other shows, the need for proper crankcase ventilation is not appreciated by many MG owners. Crankcase ventilation is not just to relieve the pressure build-up that might occur in the crankcase without it, but also to provide for the proper scavenging of combustion products that enter the crankcase. In any engine, no matter how new or in how good a condition, a small amount of the products of combustion in the combustion chamber will blow-by the piston rings and enter the crankcase. As an engine wears, this blow-by will increase. These combustion products form gases within the crankcase that can combine with the engine oil and form corrosive substances that damage the wear surfaces within the engine. Also, these gases can be combustible. The purpose of proper crankcase ventilation is to scavenge the combustion products from the crankcase before they combine with the oil, or, because they can include unburned fuel, cause an explosion within the crankcase.

The MGA has an atmospheric ventilation system. When the car is moving, air is passing by the bottom of the vent tube. The shape of the end of the vent tube is such that this passing air causes suction in the tube to draw the gases out of the crankcase. As these gases are drawn out, fresh air enters the crankcase through the vent hose connected to the valve cover. The other end of this hose is connected to the air filter to filter the air drawn into the valve cover. Some MG owners have installed after-market aluminum valve covers that do not have a vent pipe to connect to the air filter. Others have installed Weber carburetors that have an air filter with no provision for attaching the hose from the valve cover, and have plugged the tube into the valve cover.

The MGA has an atmospheric ventilation system. When the car is moving, air is passing by the bottom of the vent tube. The shape of the end of the vent tube is such that this passing air causes suction in the tube to draw the gases out of the crankcase. As these gases are drawn out, fresh air enters the crankcase through the vent hose connected to the valve cover. The other end of this hose is connected to the air filter to filter the air drawn into the valve cover. Some MG owners have installed after-market aluminum valve covers that do not have a vent pipe to connect to the air filter. Others have installed Weber carburetors that have an air filter with no provision for attaching the hose from the valve cover, and have plugged the tube into the valve cover.

If you have an after-market aluminum valve cover without a vent, it may have a vented cap with an integral filter which is OK. If the cap is not vented, then you should provide a means for venting the cover itself. The easiest way to accomplish that is to go to your local hardware store and buy a brass fitting that can accept a push-on, half-inch hose (with clamp) on one end, with threads on the other end. The valve cover can then be drilled and tapped in a suitable place to install this fitting so that a hose can be connected to the air filter. A similar fitting can be attached to an air filter if it does not have one for the other end of the hose.

For my MGB, I used an MGA valve cover, and installed a fitting for the hose in the back of the air filter. For the MGB engine in my MGA, I will do much the same – use an MGA valve cover, and attach the hose to the back of the original front air cleaner. The lower vent pipe presents an additional problem, because there is nowhere on the MGB block to attach the bracket (see Figure 1). On the MGA, the bracket is attached to one of the bolts securing a blanking plate for a mechanical fuel pump. The MGB block has no such blanking plate. My original MGB engine, although it had PCV and no lower vent pipe, had a bracket attached to the engine mount to provide a mounting stud in the same location as the blanking plate. This stud was used to secure the overflow vent tube from the carburetors. Later MGBs had evaporative loss systems whereby the overflow vent tubes from the carburetors went to a charcoal canister to collect the fumes, and the bracket was no longer required. As early as 1976, British Leyland listed the brackets as no longer available (NLA), so they are scarce. I will have to try to fabricate one to attach either to the engine mount bolt to the left or to one of the oil pan bolts below.

Editor’s Note:

More information on this important topic is available on the MGAGuru website.

Comment by: Roy C. Sperbeck

I have an aluminum valve cover ,I put an offenhauser breather on the carb side of it ,[ 90deg one] the are on ebay all the time but not cheap .My opinion is it lets the engine breath and cuts down oil leaks due to preasure build up internally.

I have instrumented and have done testing on the MGA Crankcase Ventilation system and found that the end of the tappet cover vent is not in the main airstream under the car but is instead, blocked by the frame cross member and therefore has very little draft effect. All of the blow-by gasses are in fact drawn into the air filter. For preliminary report see https://www.mgexp.com/forum/mga-forum.2/mga-crankcase-ventilation-test-results.4476585/