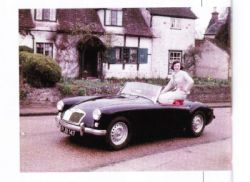

60 Years Young – The MGA Twin Cam

This year sees the 60th Anniversary of the launch announcement of the MGA Twin Cam on July 15 1958. The previous day, July 14 1958, MG had organised a Press demonstration day at Chobham complete with the Morris Works band and EX181, itself powered by a supercharged Twin Cam engine.

This year sees the 60th Anniversary of the launch announcement of the MGA Twin Cam on July 15 1958. The previous day, July 14 1958, MG had organised a Press demonstration day at Chobham complete with the Morris Works band and EX181, itself powered by a supercharged Twin Cam engine.

Somewhat surprisingly both events passed without John Thornley being in the country. He had decided to undertake a tour of US dealers and MGCC branches. It would be disingenuous to suggest that this trip was in any way connected to his 25th Wedding Anniversary, which also fell on July 15.

Contemporary reports in ‘Motoring’, which included MGCC information prior to the publication of Safety Fast!, show him travelling widely in the US although whether he made the scheduled announcement of the introduction of the MGA Twin Cam at the MGCC New York on July 15 was not reported. At the same dinner he should have received a glass Loving Cup inscribed with an Octagon on one side and an owl, Mrs Thornley’s favourite animal, the other. This was shipped out to the US by Geoffrey lley, Mr Thornley’s Assistant General Manager, from Abingdon.

The exact genesis of the MGA Twin Cam will never be known. That the project was the brainchild of John Thornley, Syd Enever and Alex Hounslow is not in doubt. The MGA was a revolutionary concept for MG following the string of traditional two-seater sports cars starting before World War II with the MG TA and culminating in the MG TF. MG’s 1955 Le Mans entries were clearly MGAs in all but name, and it is apparent that the development of Twin Cam engines, of both separate Austin and Morris design, must have been commenced prior to the MG’s 1955 Dundrod entry in which they featured.

We do know a little more about where the Morris engine originated. Gerald Palmer, the design engineer in charge of the MG and Riley drawing office at Morris in Cowley designed a new ‘top end’ overhead cam arrangement for the ‘B’ series engine as an ‘addon’ that would not require any major tooling changes to either car or power unit. With the blessing of his engineering director, Vic Oak, he sent his new design package to Morris Engines Branch for them to make a prototype.

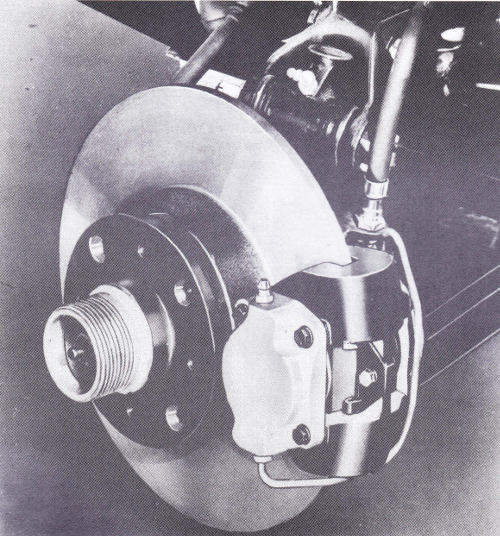

Development of the MGA Twin Cam by MG can be tracked by entries in the EX187 register devoted solely to the Twin Cam, the earliest of which is dated June 2 1955 referring to the ‘Dunlop Centre Lock Type Disc Wheel’. It is thus clear that the Twin Cam must have been envisaged as a possible variant of the pre-production MGA, at least in concept, at about the same time as the MGA project itself was being progressed.

Car manufacturers develop many concept cars nowadays but in the 1950s resources, especially at MG, were stretched so the continued development of the Twin Cam following BMC’s withdrawal from circuit racing after the tragedies of the 1955 Le Mans and Dundrod must have relied on the ongoing support of Thornley et al.

Having developed the car and even having produced the pre-production prototype what persuaded MG to put the car into production? A number of factors have been cited including the pressure coming from US dealers for the MGA for more horsepower. The US was MG’s principal market and this puts John Thornley’s presence in New York on 15 July, 1958 into context.

The extent to which the desire by MG management to have a car capable of making credible competition entries will never be known, but it may well have been a factor in proceeding to production, whereas the potential for a direct economic benefit, based on the premium over the standard car and the likely added production cost, is difficulty to justify, especially with hindsight.

This is the more so as production was said to be designed to be limited and that the Twin Cam would only end up in the hands of enthusiasts. If this was really the strategy then it was naïve to say the least because the moment demand for the car became apparent it was inevitable that the marketeers and ‘bean counters’ would take over and push for production increases, which is exactly what happened.

However, there are grounds to believe that MG knew that the engine was delicate in certain circumstances and that the professed self-imposed limit on production and distribution would have been a way of both addressing this weakness and validating a decision to proceed to production. Syd Enever and John Thornley were on opposite sides of this debate with Syd urging caution and John wanting to push ahead to satisfy the demands of MG’s US dealers.

In the event, of course, the Twin Cam engine proved unreliable in both the hands of the experienced racer and the youngsters. The result being that the reputation of not only the Twin Cam but also the MGA and indeed the MG brand itself all suffered as a result of the engine failures and warranty claims. This culminated in the 1960 cessation of production of the Twin Cam after just 2,111 had been produced – just over 2% of total MGA production. The demise of the Twin Cam received almost no publicity at the time which speaks for itself.

All the above is well known and largely documented. Perhaps casting events in their historical context gives a better understand of possibly why the car was developed and produced. Taken as a whole there seems no overarching commercial or other rationale and ultimately perhaps Thornley, Enever and Hounslow made it happen simply because they could.

As an MGA Twin Cam owner I am delighted they did.

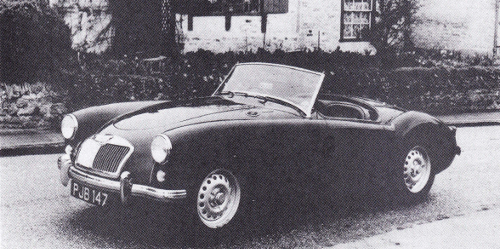

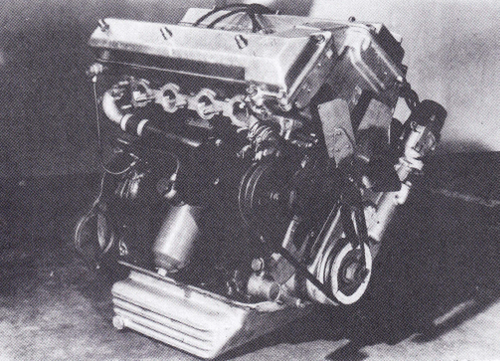

I will not recite the oft published description of the Twin Cam save to say it had Dunlop Disc Brakes all round with the attractive Dunlop knock-on wheels and a unique engine developed at Morris Engines Branch with double overhead camshafts.

The MGA Twin Cam had relatively modest success in track competition and was probably better suited to endurance events, as illustrated by SRX 210’s class win in 1960 at Le Mans and a credible performance in 1961 at the Nurburgring whilst not forgetting the exploits at Sebring. In short duration events amongst the most notable achievements was the Dick Jacobs team winning their class in the Autosport Trophy in 1960. Had the EX186 project not been cancelled after BMC withdrew from circuit racing it would have been of great interest to see how the further developed Twin Cam engine would have performed in the 1956 Le Mans event.

A question of some interest may be whether the problems with the engines encountered in period are now solved or were solved in period? This is a question on which opinions differ. Generally to satisfactorily solve a problem you have to understand a problem. MGA Twin Cam engines in period kept holing pistons. As I know from personal experience they still do so today. MG never found out why this was other than to attribute the cause to detonation, itself probably caused by running lean but in so doing that simply leaves the cause of running lean as the question. MG tried the removal of the vacuum advance on the distributor and reducing the compression ratio, with resultant loss of horsepower, as methods of solving the problem.

Jim Cox was in charge of the Development Department at Abingdon and they were charged with solving the problem. Their issue was that they could not reproduce the problem, and only once lost a piston when Tom Haig, MG’s test driver, was returning from the MIRA Test Track at Lindley, near Nuneaton, at a steady 3,500 revs. They even tried making transparent float chambers for the SU carburetors so as to see the fuel foaming, thought to be the issue, and believed to be caused by a harmonic at 2,500 and 5,000 revs. Nothing was seen. As Jim tells it, the problem was neither reproduced let alone solved, the model was discontinued and the department switched to another task.

Many of the cars today are little driven and then not driven hard so to what extent the problem persists in practice is difficult to say. My own experience was on a dual carriageway at a steady 4,000 revs and I was using Webers with flexible mounts and the perceived wisdom is that my holed piston should simply not have happened.

Getting a reliable Twin Cam engine is an important challenge because the future generations of enthusiasts who will hopefully adopt the MGA Twin Cam as their model of choice will be increasingly remote from the first or even second hand skills and knowledge, let alone the parts, required to keep these engines in workable condition.

Fuel injection may give better mixture control and resolve the problem in a practical sense. Perhaps the work-up required, which involves running the engine in a test rig with a Lambda sensor on each exhaust port, may persuade the engine to give up some of its darker secrets?

This is work in progress in which Peter Wood, the octogenarian stalwart to whom the Twin Cam community owe a great deal, is involved. He retains the original factory drawings of a proposed mechanical fuel injection system for the Twin Cam in period.

Thanks to Edward Vandyk, MGCC MGA Register Historian and MGCC Twin Cam Group Secretary for this article.