MGA SU-H4 Fast Idle Cam

(What Are the Three holes for?)

Bob Shafto – October 11, 2024

A question that comes up often is, which hole should be used in the fast idle cam and why are there three holes? Some claim the three holes for the link rod, are to compensate for linkage wear and others claim it is to adjust for climate (cold climate vs warm cold climate). I was inclined to agree with the climate theory but have to admit I didn’t really know. There is no factory documentation from BMC or SU so I pulled out my spare carburetor and did some simple testing hoping the answer would present itself.

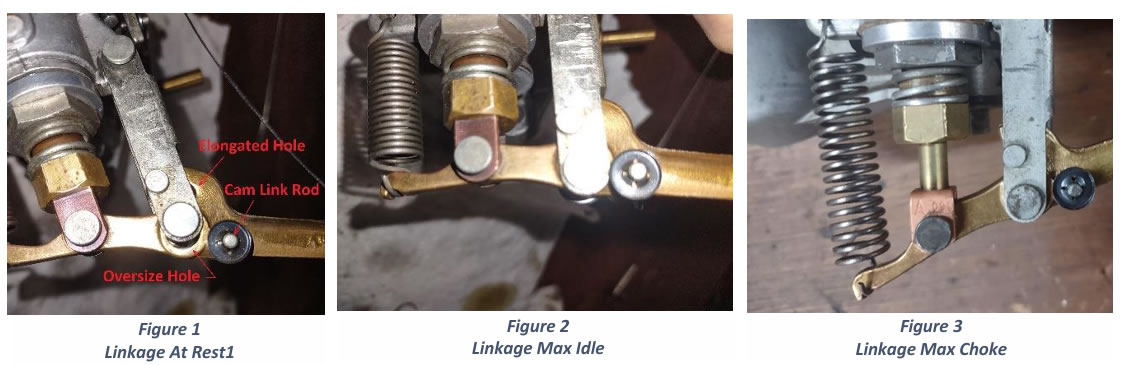

The first thing that becomes obvious is, fast idle and choke are two completely different mechanisms. The choke is operated solely by the brass link arm (completely independent of the cam function) below and to the rear of the front carburetor mating with the brass link arm of the rear carburetor. The fast idle cam solely controls fast idle (nothing to do with choke function). The linkage below the carburetor, has two pivot points, one is an oversize hole at the bottom pivot point and an elongated horizontal hole at the upper pivot point that allows some free movement before pulling down the jets. This is designed specifically for the fast idle cam. When the choke cable is pulled, it raises the choke arm which in turn raises the cam rod, rotating the fast idle cam. The free play allows the cam rod to move vertically to rotate the cam, without adding more fuel. The choke on these carbs does not restrict air but adds fuel instead. Notice that the cam rod connection to the choke linkage in figure 1, is below the lower linkage arm pivot point at rest. In figure 2, it is level with the lower pivot point and all the free play in the pivot points has been taken up, the cam has rotated about 20° and idle has increased several hundred rpm. At this point, further pulling of the choke cable will begin to pull the fuel jet down allowing more fuel to flow past the needle in the carburetor throat. In figure 3, the fuel jet has been pulled down to its max. The total cam rotation is 40° with 20° of idle adjustment before moving fuel jet. The idle will continue to increase while the fuel jet is being pulled down.

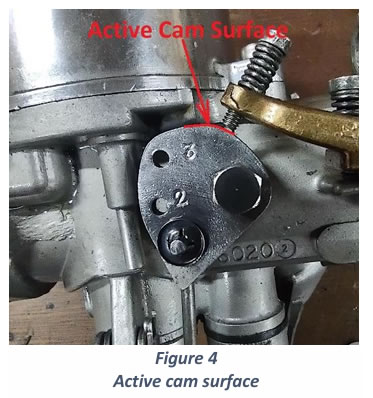

The cam rotates around the mounting bolt about 40° total, so the fast idle cam function is only a portion of the cam itself (figure 4). The vertical movement of the cam link rod, is controlled by the link brass link arm under and rear of the front carburetor. The vertical movement of the link rod is about ½”, limiting the possible rotation of the cam and is a function of the linkage design below the carburetor. The first 20° of rotation is before the fuel jet begins to be pulled down.

The cam rotates around the mounting bolt about 40° total, so the fast idle cam function is only a portion of the cam itself (figure 4). The vertical movement of the cam link rod, is controlled by the link brass link arm under and rear of the front carburetor. The vertical movement of the link rod is about ½”, limiting the possible rotation of the cam and is a function of the linkage design below the carburetor. The first 20° of rotation is before the fuel jet begins to be pulled down.

The holes are spaced 30° apart and equal distance from the center so each hole rotates the cam, the same amount. There is no change to the profile so the hole in use, only changes the starting point and distance from the adjusting screw arm.

Now a look at what happens with the cam rod link, in the 3 possible positions.

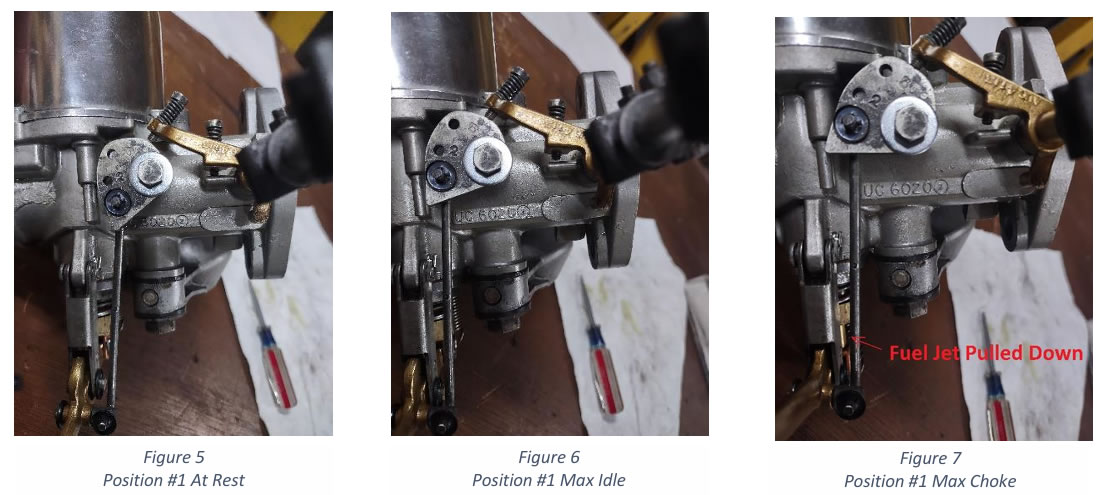

Position #1, gives a long gradual throttle increase before the jet begins to pull down (active choke). Figure 5 shows the linkage at rest (choke cable pushed in against the dash). Figure 6 shows the linkage at the max position before pulling the fuel jet down adding more fuel. Figure 7 shows the linkage with the fuel jet pulled down as far as it can go.

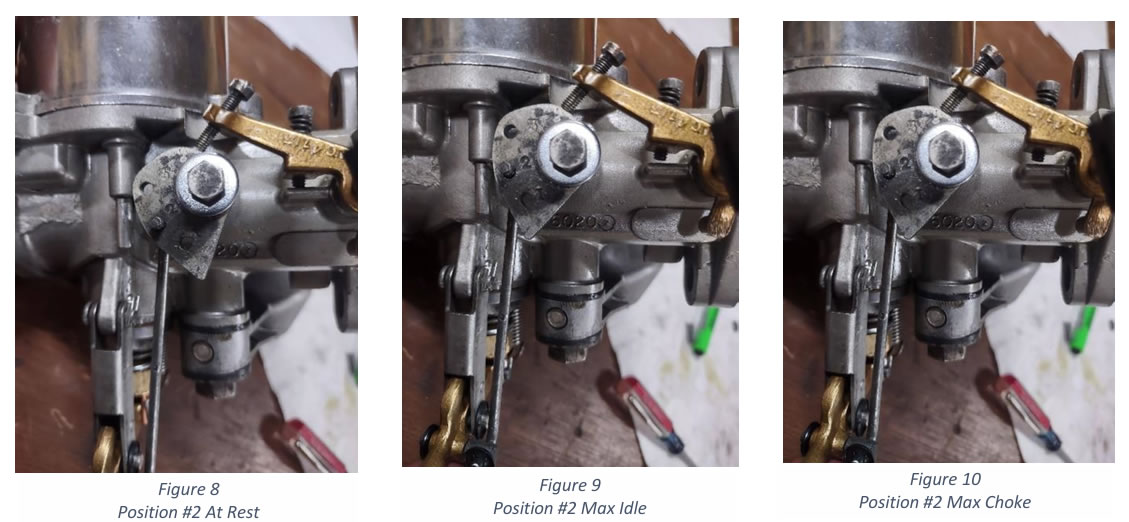

Position #2, reduces the amount of idle control. Notice that the cam is rotated downward, away from the adjustment screw at rest and requires the fast idle adjustment spring, to be removed to get proper adjustment. This spring acts like a lock washer, resisting the screw from backing off yet allows height adjustment and should not be removed. This also tells me that “different holes are to adjust for linkage wear” theory can’t be true because it has moved the cam too far for any possible linkage wear. The adjustment screw is at an angle to the cam which will increase wear.

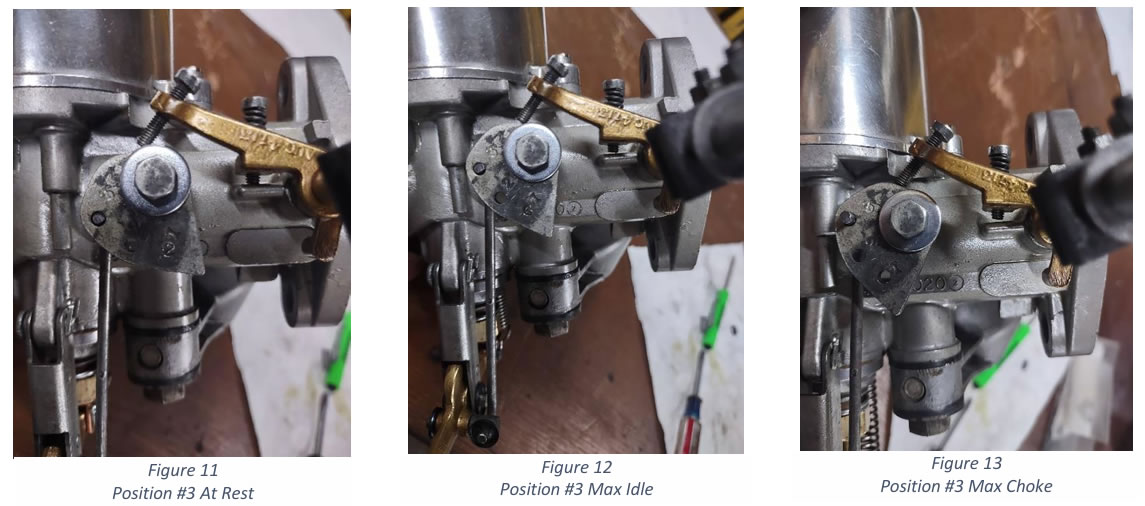

Position #3, is even worse. Again the idle adjustment spring must be removed and almost no idle control before choke and the adjustment screw angle to the cam is sever causing increased wear.

Neither of the theories for the 3 holes in the fast idle cam can be true. There is way too much change in cam rotation and adjustment screw clearance to account for linkage wear and too little, idle adjustment to account for climate differences.

Some have suggested that to use holes #2 and #3 you have to change the linkage rod, but only one length is offered for the MGA and my guess is that, lengthening the rod to the point of reasonable idle control would place the cam in the same position as the standard rod in position #1. To adjust for wear or climate you would have to change the cam pivot point not rod position or length. Most likely, the factory intended that the MGA use only hole #1.

The only way to change cam lift characteristics, is to change the cam profile or move the cam center rotation point. So why have 3 holes? It appears that they are for different applications, recognizing that the SU carburetor was used on a variety of vehicles.

The only way to change cam lift characteristics, is to change the cam profile or move the cam center rotation point. So why have 3 holes? It appears that they are for different applications, recognizing that the SU carburetor was used on a variety of vehicles.

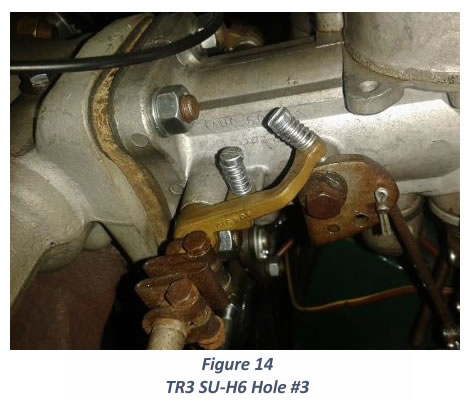

Here is one fitted to a TR3 with SU-H6 Carburetors using hole #3.