Working Inside the Octagon (Part 2)

The MGA was selling well but John Thornley didn’t want the grass growing under anyone’s feet regarding its replacement. Now that he had his design department up and running it had to earn its keep.

The MGA was selling well but John Thornley didn’t want the grass growing under anyone’s feet regarding its replacement. Now that he had his design department up and running it had to earn its keep.

From time to time I would be given pictures of concept cars from magazines to trace for Syd Enever. One that stands out was of the futuristic ‘Super Flow’ Alfa Romeo by Farina in the October of that year. With its recessed headlights, wrap around windscreen and overstated tail fins it may have been the original inspiration for the MGB.

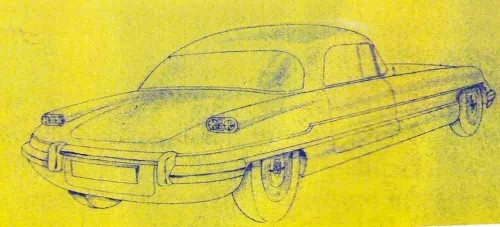

At the end of 1956 I was given a couple of Syd Enever’s rough sketches of a new two-seater coupe and instructed to trace them onto proper drawing sheets. The sketches were rather out of proportion and I asked Jim’s permission to alter them. “Better not,” was his reply, “Syd doesn’t like his ideas being changed, so keep them as they are.”

The completed drawings went off to Syd’s office and were sent back a few days later with the roof line changed to accommodate a 2+2 arrangement (probably at John Thornley’s insistence) with a request for colour versions (he had picked out the colours he wanted from his ICI industrial paint sample catalogue). He also instructed that they were to be painted on neutral grey art board. The onIy board we couId find wasn’t really suitable for water colours but had to suffice. I once again raised the question of the perspective and was told quite firmly not to change anything. A front and rear view were duly delivered to Syd and things went quiet again. I think however that this can be considered to be the beginning of the long process that finally gave us the MGB as we know it today.

Although quite different to the final version, the basic ingredients were there: the recessed headlamps, the straight through wing line, the wrap around windscreen and the partly shrouded rear wheels. By the way, don’t be fooled by the ‘MGC’ badging; at this point in time it was intended that the ‘Twin Cam’ would be known as the MGB. Neither should anything be read into the ‘1958’ on the number plate. Just a bit of wishful thinking on the part of yours truly! We must not forget either that whatever body style evolved it would have to fit onto the MGA chassis with the minimum of modifications. Any thoughts of a monocoque construction at this stage would have been completely ruled out on grounds of cost.

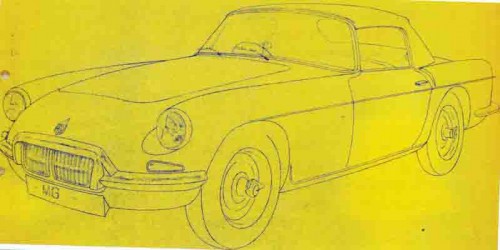

As 1957 progressed, further sketches were made using EX18I as a possible starting point. Whilst Jim was busy creating a ¼ scale, I was once again asked to produce a three dimensional coloured drawing for Syd to consider. This included new grille and bumper treatments. Around the middle of the year the experimental number EX205 was raised and Don Hayter became involved in the project that he, under Jim O’Neill’s expert guidance, would see through to production and beyond. Model maker Harry Herring also began making the first of what would eventually be a whole series of models as Syd sought the definitive shape for his new car.

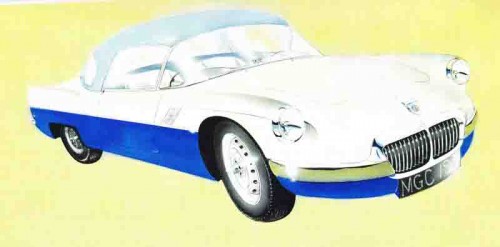

Syd had already discussed his ideas for the new car (MGB) with George Harriman, BMC’s deputy Chairman. He had a great deal of sympathy for what Syd was trying to achieve but suggested looking to Italy, who at this time were the acknowledged world leaders in body design, for ideas. To this end Harriman commissioned the small Italian styling house of Frua to supply a finished body on an MGA chassis. When it arrived at Abingdon it caused quite a stir and certainly gave Syd food for thought. The main criticism seemed to be that the front end treatment looked too aggressive for an MG. It would in any case cost a small fortune to tool up; money that Abingdon didn’t have. The interior and especially the fascia panel would also be too expensive to manufacture.

The car was wheeled away into a corner of the shop and covered with a dust sheet, although not before a ¼ scale drawing was made, I believe, by Don Hayter; from which Harry Herring then made a beautifully accurate model. This model survives to this day at the Heritage Museum at Gaydon. The Frua car was also of course photographed thoroughly and I was given one of these pictures to trace and add in Syd’s idea of what the front end should look like. Whilst the new front end treatment was less dramatic than Frua’s it was still quite distinctive. It also retained Syd’s key feature – the recessed headlamps. I think then that this must be regarded as quite a significant step on the evolutionary path towards the final design. Harry Herring made a 1:4 scale model of this version too, which can also be seen at Gaydon. I really think these models are an extremely important source in tracing the early history of the MGB.

The Experimental department had been busy too. Although all racing had been stopped, BMC Chairman, Leonard Lord, had allowed record breaking to continue as part of the motor sport programme. It was agreed however that all work on record cars would remain under the control of the Engineering department: i.e. Syd Enever and Alec Hounslow. In fact the Competitions department had already moved out and into another unit at the opposite end of ‘B’ block (the part of the MG factory that still remains). Both Experimental and Competitions needed this extra space, especially now the latter was also preparing customers’ rally cars.

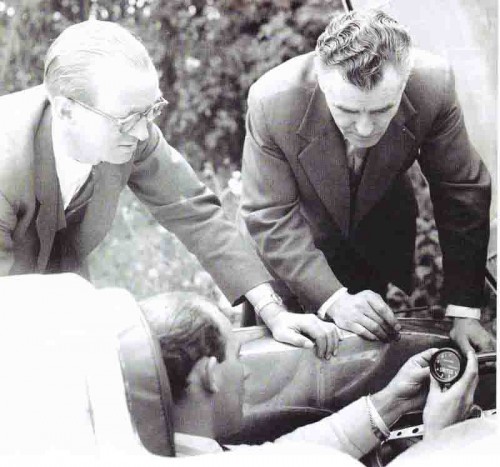

The previous year (1956) EX 179, the MGA based record car, had been fitted with an unsupercharged version of the Twin Cam engine. Out on the Utah salt flats in August that year the car acquitted itself well, bagging a clutch of records from 10 miles to 12 hours under the supervision of Alec Hounslow and Henry Stone and of course the ever watchful eye of George Eyston. For 1957 it would be the turn of the mid-engined EXI8I. Terry had spent the past year watching the lads in the shop turn his meticulous drawings into the most remarkable record breaker that Abingdon had ever seen. A stabilising fin had been added to Terry’s initial design at the insistence of George Eyston for added safety in the event of the car going off course for any reason. Shipped out to the States in a crate on board the giant Cunard liner “Queen Mary”, the car would then make its way overland by rail to Wendover, the nearest town to the salt flats. Alec and Henry once again made the trip, accompanied this time by Syd Enever. One glaring omission from the support team was Terry Mitchell, the car’s main designer. This demonstrates just how tight the budget was at that time that Terry’s presence, as part of the team just couldn’t be justified. It must however be remembered that travel to America in those days was a very expensive business compared with today. Despite being dogged by bad weather, EX181, driven by Stirling Moss, managed to make a two way run on the still damp salt and achieve a speed of 245mph with the supercharged 1.1½ litre car that was more or less straight out of the box!

Back in Abingdon Don Hayter began laying out the full-scale skin lines for the first attempt at EX205. These were transferred to Eric Carter at Bodies Branch where a full size model was made for viewing. This has subsequently been criticised for looking heavy but it must be remembered that it was designed around the MGA chassis with its 94 inch wheelbase and I5 inch wheels (these dimensions would eventually be reduced for the production ‘B’). It was also designed as a 2+2 coupe, which didn’t flatter it at all. I don’t believe the blue and white colour scheme (pale blue roof, white upper body and darker blue lower body surfaces) did it any favours either.

A number of other projects were engaging the minds of the Abingdon design office at this time, amongst which was a facelift Riley Pathfinder based on the Wolseley Six-Ninety (I did a coloured rendering of this too for Syd, in a two tone colour scheme of his choice that actually found its way into production). This facelift, engineered at Cowley, went into production at Abingdon as the Riley TwoPoint-Six. Then there was the new Riley I .5 which was initially put into production at Abingdon but was then switched to another location within the group after only I50 cars had been completed (Syd had a hand in the front end style of this too). In exchange for losing the Riley, production of the new Austin Healey I00/6 was moved to Abingdon from Longbridge and rumours of a new Midget size sports car began to circulate.

It soon emerged that this was the all-new Austin Healey ‘Sprite’ and although it came from Longbridge fully engineered, Abingdon would be responsible for all ongoing design work. Jim handed day-to-day responsibility for the body content to Denis, not realising just how soon they would become enmeshed in engineering problems. Syd had arranged for a production prototype to be tested on the pave at the MIRA test facility, which soon began to show up a weakness in the design of the body shell. The body began to buckle in the area of the rear wheel arch after just a short time on test. A great deal of midnight oil was burned in finding an immediate solution to this problem, because, in point of fact, the first batch of production cars were already going down the line!

At about this time Rootes Group in Coventry decided to build a new small car. This would eventually become known as the Hillman Imp. They were actively recruiting a new group of senior engineers for the design team and one of those persuaded to join them was MG’s Harry White. I remember that Syd insisted that Harry must pass on all his knowledge of road springs including formulae to one of the other members of the chassis section before he left, to avoid being left high and dry. I think Bob Staniland was chosen for this task because firstly, he had already done some spring calculations for Harry and secondly, he had seemed to inherit Harry’s love of the slide rule. These were of course the days before pocket electronic calculators had been invented by a certain Mr Sinclair!

Harry’s departure left a sizeable gap in the chassis team but fortunately Terry Mitchell, despite an aversion to all aspects of administrative paperwork, agreed to step into the breach. This was most important as it ensured the continuity of effort, so vital in such a small team. He was also given the title Chief Designer, Chassis with Jim O’Neill becoming Chief Designer, Body. At the same time Roy Brocklehurst became Chief Chassis Draughtsman whilst Don Hayter inherited Jim’s old title of Chief Body Draughtsman. Before his move to Rootes, Harry had been working with Roy on a form of independent rear suspension, in an attempt to get away from what was considered by this time as the old fashioned arrangement of ‘cart springs’ with a solid back axle. This was driven both by a desire to improve the handling and the fact that the market was beginning to dictate that any self-respecting sports car, especially one that had pretensions of being a car that you could take on the racetrack, should have a form of all round independent suspension. Harry had studied closely all the cars on the market that featured either fully or semi-independent rear suspension systems before opting for a relatively straightforward independent set-up with radius arms and coil springs. It is understood that such a system was built into a development MGA but Syd’s inbuilt aversion to IRS as the result of his experience with the pre-war R-type, coupled with Tractor & Transmissions Branch’s reluctance to manufacture a special differential unit just for MG, meant that there was no particular enthusiasm for going down this route.

When Harry White left, Roy carried on with the rear suspension programme. Terry, meanwhile, favoured a de Dion tube arrangement. He had already designed such a system for the EX I8 I record car using quarter elliptic leaf springs set at an angle to the axle, in spite of the fact that this car was only ever intended to go in a straight line or at most a 10 mile diameter circle, on the salt flats! It was agreed therefore that recently recruited Dick Wright should work on the design of an alternative scheme utilising the de Dion principle, which would be fitted to the chassis that had been prepared for the cancelled (1956) EX 186 Le Mans car. This consisted of a large diameter de Dion tube connecting the wheels with, interestingly, conventional semi elliptical leaf springs as the suspension medium. Also, although rear disc brakes had been seriously considered, drum brakes were finally decided upon for this exercise. These schemes were of course never intended for the MGA (although a special racing version of the Twin Cam with IRS may have been considered at sometime in the future) but would instead be engineered into the ‘A’ successor.

Thank you to the MG Car Club and Pete Neal for allowing us to reproduce this article from Safety Fast magazine.