Working Inside the Octagon (Part 3)

It was mid-1958 before things began to really pick up again on the MGB project. A new EX number, EX214, was allocated and at this point a number of engine options were being investigated. One of these was a brand new V4 power unit designed by Longbridge.

It was mid-1958 before things began to really pick up again on the MGB project. A new EX number, EX214, was allocated and at this point a number of engine options were being investigated. One of these was a brand new V4 power unit designed by Longbridge.

Tested in an MGA at MIRA in prototype form towards the end of December 1958, it was hastily put on the back burner (and never to see the light of day again) when Longbridge realised what kind of tooling costs they would be faced with. A V6 version had also been designed but this apparently never got beyond the drawing stage.

An interesting development at this point was the decision to go with a 91inch wheelbase, a full three inches less than the MGA. As the decision to go for mono-construction had yet to be ratified (after all where would all the tooling money come from?) this was quite a bold move. We will probably never know quite how John Thornley managed to persuade Pressed Steel to eventually amortise a large part of the tooling costs into the piece price, but without a doubt it did remove a huge barrier from the path of the new car. In fact it brought down the tooling price from £600,000 plus, to something well under half that in return for a £2 per bodyshell increase. One of Abingdon’s briefs when designing the new car had been to make it £50 cheaper to produce than its predecessor. This was another reason to go monocoque, as the MGA’s chassis, manufactured in-house, was becoming quite an expensive item to produce because of the amount of handwork involved.

As if he didn’t have enough on his plate already, in November 1958 AD026, the revised ‘Big Healey’ 100/6, was added to Syd Enever’s list of responsibilities. This would become the Austin Healey 3000, availabIe in two and four-seater versions having a much-modified six-cylinder engine with the capacity increase to 2.9 litres.

At this point I was instructed to create an up-to-date coloured picture showing the car with its new front end as well as the finalised rear end treatment, for Syd to take to show George Harriman at Longbridge, with whom he had a good rapport. I had thought this to be my best effort so far, as I was finally beginning to get the hang of using the airbrush. Unfortunately that was the last I ever saw of it as the drawing was never returned to Abingdon. Jim told me some years later that he had seen it displayed on the wall of an office in the ‘Kremlin’ at Longbridge. Recognition at last – or perhaps they just needed something to cover a damp patch …

Roy continued to test various alternative schemes for the rear suspension on EX214/AD023. At one stage it was proposed to use radius arms with coil springs and telescopic dampers with lateral location by Watts linkage. This was tested on a development MGA (LJB 370) and put through its paces at the MIRA test faciIity at Nuneaton. It was whilst returning from one of these test days in March 1959 that Roy had the misfortune to turn the car over. This occurred on a nasty S-bend at the bottom of Boars Hill when they were almost back at Abingdon. Apparently one of the rear wheels got caught up in the rear wheel arch on full bump and sent the car cartwheeling into a ditch. Fortunately Roy and his passenger were uninjured apart from a few cuts and bruises. This, I think, underlines the fact that however much testing is done on the track there is no substitute for actual road proving.

LJB 370 was rebuilt in Development in just two weeks (one of several reincarnations) and a further two weeks later was back on test at MIRA. This time the Watts linkage, ruled out on grounds of cost, had been replaced by a Panhard rod. A couple of days later the car was also put through its paces at the Dunlop test facility at Halfpenny Green. This set-up was built into the first running prototype ‘B’ but would eventually be ruled out as being too expensive. The fact was that unfortunately none of the proposed changes showed any significant improvement over the tried and tested arrangement of live axle with leaf springs and lever arm shock absorbers. At least not enough to justify the on-cost involved. In the end, the cheapest solution, as was often the case at Abingdon, won the day.

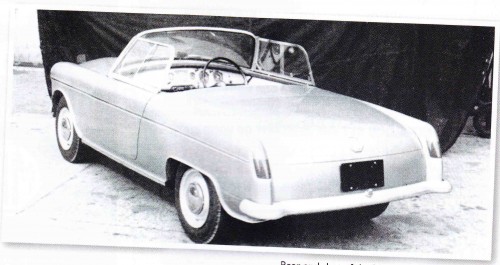

On June 3 1959, Syd Enever was allocated project number AD023 by Longbridge. This was the official go-ahead to commence the production engineering. This was a major step forward as it meant that the MGB had now won the approval of the main board and that budgets should now be forthcoming. This is not to say that it could not be cancelled at some future stage (some were) but at least it was now ‘on the radar’. For the small Abingdon design team it was now ‘all systems go’. It must be remembered however, that at the time there were other projects competing for attention within the department. One such project was EX220, the Mini based sports car that Jim O’Neill had started work on back in February. This would have a wheelbase extended by approximately three inches over the standard Mini, whilst the overall length would increase by some sixteen inches. The body style resembled a scaled down version of the AD023. Even at this early stage Jim had decided to use 12 inch wheels rather than the standard 10 inch rims to improve the car’s proportions. It was planned that there would be both MG and Austin Healey versions to widen its appeal. Syd Enever had, of course, immediately seen the potential of this ground-breaking little car and felt that there would be a ready market for a two-seater sports version of it. Sometime around 1960 EX220 progressed to having the corporate AD034 number bestowed upon it but after a fair bit of work had been done including a new body designed by Farina, Alec Issigonis, who was fiercely protective of his new baby, eventually killed it off describing it unfairly as a “dreadful thing”.

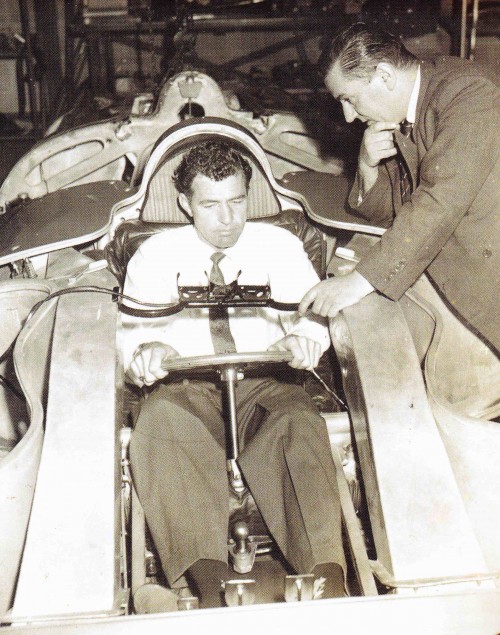

Also at this time, the department was engaged in supporting the 1959 record attempt. Although EX18I would be going more or less unchanged from its previous visit, it was planned, for publicity purposes, to take an Austin Healey ‘Sprite’ as well on this occasion. Don Hayter had designed a streamlined body very similar to EX179 around a production ‘Sprite’ body tub, designated EX219. Unfortunately, due to the problem of fully enclosing the front wheels (leading to a larger frontal area) the car did not perform well in the wind tunnel. Subsequently it was decided to take EX179 fitted with a ‘Sprite’ engine, call it an Austin Healey ‘Sprite’, and keep the designation EX2I9 for it anyway. Both of these cars needed to be shipped in early August for an attempt on the Bonneville Salt Flats in September. Once again in spite of wet conditions at Utah both cars acquitted themselves well with EX18I, driven this time by Phil Hill, achieving a maximum speed of 254.91 over the flying kilometer and EX219 picking up 15 records from 50km to 12 hours. It was felt by the team that had the salt been in better condition 260 mph could fairly easily have been attained. Syd’s (and George Eyston’s) ambition had been to eventually reach 300mph with this remarkable little car but Leonard Lord soon put the kibosh on this idea by announcing, on their return, that there would be no further record attempts and that the Abingdon engineering department would forthwith devote all their energies to the design and manufacture of production cars.

On this return from America, Syd Enever found yet another project in his in tray. This time it was ADO41, the Sprite facelift. The Healey team had restyled the front end; now it was up to Abingdon to complete the engineering in conjunction with Pressed Steel. Just a few months later, in February 1960, Syd was landed with the further task of turning the Sprite into a new ADO47 Midget. As most of the content for these two projects was body related it fell once again to Jim O’Neill and Denis Williams to pick up the baton. There was also an additional requirement for the new Midget: a boot lid! This was something the Sprite had never had, which meant a re-engineered rear end was required. Jim resurrected his EX220 design and blended it in the best he could with the Warwick designed front end which couldn’t be changed, apart from the grille, at this late stage. When the Healey people saw Jim’s new boot they insisted it went onto the Sprite too. It made sense anyway to have a single bodyshell for the two models. Introduced to the public in the summer of I96I these two models would prove to be a great success.

Fortunately at around the time the new Midget project was getting underway Jim had been able to recruit Don Butler from Cowley once more, only this time permanently. Don was therefore able to support Don Hayter with the quite daunting task of the detail engineering of the MGB. The prototypes for both the Midget and the ‘B’ were progressing in the Experimental shop at Bodies branch under the ever watchful eye of Eric Carter.

Earlier in 1959 it had been decided to at last build the special ‘Le Mans’ body for EX186. John Thornley’s idea was that the car could be entered in the race as an ‘MG Special’ under the auspices of the MG Car Club. The car was sent to Midland Sheet Metal at the beginning of May and returned a couple of weeks later, with its beautifully streamlined aluminium body ready for painting. Unfortunately someone in high places had got wind of what was going and sadly Abingdon was forced to cancel the whole project. The car was quietly completed and then put under a dust sheet in the corner of the shop where it stayed until the beginning of 1961 when it was spirited away to America.

With little more than a year of my (five year) apprenticeship left Syd thought it would be a good idea for his two apprentices to “get their hands dirty”. This was put in the hands of the Personnel Department to organize. For one reason or another it didn’t actually happen until the spring of 1959 when we were both sent off out into the factory. I say the factory, but in fact I think Bob went into the Competitions Department whilst I was destined for the Development Shop for the next four months. For this I was told to report to show foreman Alec Hounslow. “Wait there”, he said, and disappeared out into the shop. Minutes later he reappeared and said, “You can go on engines with Jimmy Cox”. This was the start of a life-long friendship with Jimmy that has endured to this day. Jim taught me quite a lot about power units during this period on his section; something I’ve always appreciated. I think he found me a willing pupil most of the time! I learned something of the mysteries of the ‘Twin Cam’ at this time but without doubt the highlight for me was being allowed to assist Jim in building up the engines for the ‘Sprite’ record breaker that would be going to Utah with EX181 (and Jimmy) later that year. Part way through this spell I was ‘borrowed back’ for a couple of weeks by Jim O’Neill to create a ¼ scale assembly drawing from Don’s full scale layout. I remember that at this time AD023 still retained Syd’s original style grille (similar to that on EX205) and Roy’s coil spring rear suspension.

After my stint in Development it was off to Goods Inwards Inspection for a month, then the Tool Room and finally the Show Shop under the strict supervision of Tim Binnington and Jack ‘Lofty’ Mansell. I was lucky enough to be there at Motor Show time which meant I spent a fascinating day at Earls Court helping to set up the stand. It was whilst in the Show Shop that I was told by Tim one day to “wash your hands, get your overalls off: tidy yourself up and report to Mr Thornley’s office immediately”. After waiting for what seemed an eternity (probably about ten minutes in reality) in his secretary’s office, I heard his voice boom “Come in, Peter,” and after shaking my hand he presented me with my ‘Certificate of Apprenticeship’. After a short conversation and a final “good luck old boy”, I was ushered out and sent on my way. There was just one more obstacle to my rejoining the drawing office. The official completion of my apprenticeship meant that I was now eligible for National Service which had been deferred from the age of eighteen. Sure enough my call up papers plopped through the letterbox all too soon, much to my dismay. However I had two pieces of luck. One was to manage to talk my way into the Royal Air Force, and the other was to get myself posted to Malta for 18 months! This more than made up for the six weeks ‘square bashing’ and the somewhat tedious trade training.

By the time I arrived back in the Abingdon design office in June 1962 the ‘MGB’ was getting close to production. It was, nevertheless, destined to keep me busy one way or another for the next I8 years! Indeed the ‘B’s longevity is a great tribute to its creator Syd Enever and his small but talented team of designers led by Jim O’Neill and Terry Mitchell. It seems quite remarkable that we are now celebrating the 50th anniversary of its introduction.

Thank you to the MG Car Club and Pete Neal for allowing us to reproduce this article from Safety Fast magazine.