MG Abingdon – A New Direction Part 1

The news that everyone in Britain had been dreading finally came on September 3 1939. The country was once again at war. In the light of this news a meeting of the main Morris Motors board was convened to formulate a strategy for the company as a whole.

The news that everyone in Britain had been dreading finally came on September 3 1939. The country was once again at war. In the light of this news a meeting of the main Morris Motors board was convened to formulate a strategy for the company as a whole.

The only real decision to emerge from these deliberations seems to have been an instruction to clear the many factories in the group of car making equipment in readiness for whatever Government contracts might come their way. Abingdon was faced with a particular problem in this respect. Being a relatively small factory there was simply no spare storage space for the hundreds of tons of valuable car parts to be moved. This was overcome (at some considerable expense) by the acquisition of a rather dilapidated building, a one time clothing factory, in the heart of Abingdon town centre. A great deal of work then ensued to get it into a usable condition. At that time East St Helens Street where these premises were located was extremely narrow and hardly suitable for large lorries. The problem was solved by Syd Enever and his small team in the tryout shop (the old experimental) with the construction of a one-off tractor unit using whatever old car parts they could find lying around. Known as “Bitsy” it soon became a familiar sight winding its way through the narrow streets with its several trailers filled with everything from chassis frames and engines to the dismantled paint plant that had had pride of place in the middle of the assembly building.

If MG had been expecting wartime contracts to flow from the various government ministries they were to be sorely disappointed. Neither was anything forthcoming from Cowley. They were simply much too busy finding work for their own (Morris) factories. Miles Thomas who had taken over responsibility for the Wolseley factory was equally committed to finding work for this, the largest of the Birmingham factories. As Propert was to write later, “so at the end of 1939 we found ourselves with a completely empty factory and no work to do:’ Cousins was equally succinct, “Cowley passed on no contracts to MG at this time they completely ignored us”

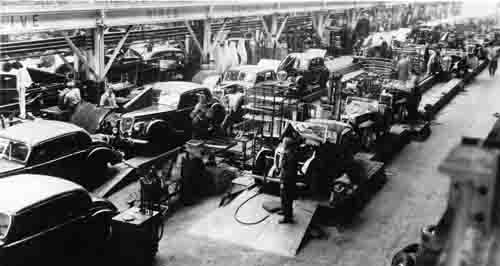

At this point Kimber and Propert decided to take matters into their own hands and start looking for work. They toured the various ministries literally camping on their doorsteps in order to see someone. After a couple of false starts they managed to gain a contract to overhaul a number of light armoured track vehicles. This was an important starting point as it would eventually lead to the company receiving major tank work. Imagine their surprise when out of the blue they were offered a contract for some aircraft work. This would entail building the whole front section, known as the G.1, of the Albermarle twin-engined light bomber. Not wishing to turn work away, they agreed, after much discussion and with their hearts in their mouths, to take the job on. It wasn’t until later that they discovered that at least three other companies, one with aircraft experience, had already turned the job down. So, with the ‘Marble’ project, as it became known, at one end of the factory in the care of Cecil Cousins and tank work at the other under the control of Sydney Enever, the factory was buzzing once more.

In 1940, Oliver Boden, the man who had been Lord Nuffield’s deputy since the departure of Leonard Lord, died suddenly, throwing the group into disarray. Anxious to get things back on an even keel, Nuffield appointed another of his favourites, Miles Thomas, as his new deputy. Thomas, who had in any case always seen himself as Nuffield’s natural successor, threw himself into the job of integrating the whole of the Morris or Nuffield Organisation as he now called it, under a single umbrella. Irritated by Kimber’s lack of enthusiasm for this idea and after a relatively minor disagreement between them, Thomas motored to Abingdon at the end of November 1941 and dismissed Kim on the spot. Miles Thomas later described Kimber as being ‘thunderstruck’ by this action, but with the country being at such a low ebb there was little he could do but accept the decision with as much good grace as he could muster. Informing the local press that he had resigned his position at MG with immediate effect, he handed over his responsibilities to H.A. Ryder who had been appointed to take his place. Everyone of course knew that it was really the capable George ‘Pop’ Propert who would really continue to run the company on a day-to-day basis.

1942 saw the company move from repairing and modifying tanks to actually manufacturing them. During the course of the war Abingdon built a total of 210 Crusader tanks, 50 Oerliken tanks and 215 Bofors tanks as well as converting 574 Churchill tanks to AVRE (Armoured Vehicle Royal Engineers), many of which were used during the ‘D-Day’ landings. On the aircraft side 653 Albermarle G.1 units were built with another 285 being completed for another factory. In addition to these, some eight and a half thousand Lancaster power units were assembled with their accompanying engine mounts, whilst the press shop turned out hundreds of thousands of detail parts for a variety of applications. The workforce, from Propert down, were justifiably proud of their achievements. Cecil Cousins summed up the situation in a nutshell when he said later, “What we did before the war was nothing to what we achieved during the war’:

After leaving Abingdon, Kim had spent the best part of a year at the Charlesworth coachbuilding company before accepting a post with the Specialloid piston company to reorganise their production facilities. Around this time he also began to talk seriously to family and friends about retiring once the hostilities were over. Sadly he didn’t get the opportunity as, on February 4 1945, he became the victim of a freak accident. Travelling to Peterborough on the 6.00pm train from London’s Kings Cross railway station, the locomotive hauling the train lost traction on the slight uphill gradient out of the station and slid backwards into the carriages of another train on platform 10, causing the rear coach to rise in the air and collide with a signal gantry. Two of the passengers were killed on impact, one of whom was Cecil Kimber. So ended the life of a man who had had such a major impact on the British motor industry, and whose company and its special brand of sports cars would become a household name, not just in Great Britain, but around the world in the decades to come.

Meanwhile, back in Abingdon, the Government contracts that had been keeping the factory so busy since 1940 were now gradually coming to an end. It was time to think about building cars once again. The question was what? Conditions in post-war Britain were totally different to what had prevailed in 1939. Most things were in short supply. Food was on ration as was clothing, petrol and just about everything else. The country was virtually bankrupt and austerity reigned. Luxury goods, if you could get them, were almost taxed out of existence and could not even be contemplated by ordinary people. It was in this atmosphere that the incoming government that replaced the wartime coalition decided that Britain must trade her way back to prosperity. To this end manufacturers would be allocated supplies of scarce basic materials on the basis of their goods being sold on the export market. There was little point in Abingdon attempting to build cars such as the well-appointed S,V,W range that had been their mainstay in the latter part of the 1930s. Where would they find a market for these cars, even in the unlikely event that the materials could be found to build them? The compact 1¼ litre saloon that Cowley had designed in 1939 and originally intended for launch in 1940 was not yet ready for production and would now have to take its place in the queue behind the Morris and Wolseley models.

This left MG with just the two-seater TB with its XPAG engine that had replaced the TA shortly before the outbreak of hostilities. It was decided to limit any changes to those necessary to overcome problems that had been encountered in service (the sliding trunnions noted for excessive wear were replaced by shackles for instance), whilst the body tub was made marginally wider although retaining exactly the same style. Renamed the TC this stop gap car began limited production on September 17 1945, with a total of just 100 cars being completed by the end of the year. Whilst there was unsurprisingly little interest in these cars at home, the company found that there was a ready market for them overseas. This was of course key to them getting supplies of the necessary materials, and the following year saw output rise steadily to 1,700 cars.

April 1947 at last saw the introduction of the long awaited V-type saloon. Whilst rather dated in its appearance and with a somewhat sluggish performance, thanks in part to its single carburetter set up, it did have some plus points that helped it to sell in reasonable numbers both at home and abroad. Chief amongst these was the coil spring independent front suspension system with its precise rack and pinion steering, considered to be seriously state-of-the-art at this time. Another useful sales feature was the built in Jackall jacking system not usually to be found on cars in this price bracket.

Over at Cowley, Lord Nuffield was getting restless. He found it difficult to accept the new modern designs of his cars. He particularly disliked the shape of the Morris Minor, calling it a poached egg. Thankfully he approved it without much change and it went on to become one of the most successful Morrises ever, both numerically and commercially. He nevertheless decided that changes were necessary to the management structure and to everyone’s surprise the first casualty was his deputy, Miles Thomas. With Thomas out he then took the axe to his board of directors. At least six of his senior managers were shown the door including Harold Ryder. Nuffield now made Reginald Hanks, who had been elected to the board along with S.V. Smith the previous August, his new deputy chairman. As a result of these changes, Smith (or S.V. as he was generally known) became the director responsible for Abingdon.

In the summer of 1948 the decision was made to transfer Wolesley car production to Cowley in order to rationalise the model range. Once this had been completed the board began to look at their other subsidiary, Riley Cars. In the November an individual by the name of Robinson came to look at MG’s production facilities with a view to transferring the whole lot to the Riley factory in Coventry. Somehow Propert, Thornley and Cousins managed to talk him out of this idea and as a consequence Riley production was instead moved to Abingdon in the May of 1949, whilst their factory was turned over to the production of engines for the Nuffield group.

If Cecil Kimber had been the captain of the ship, George Propert had surely been the helmsman who had guided the MG Car Company through many a stormy sea. Having reached retirement age it was now time to hand over the tiller to his successor. No doubt he would have preferred this to be the home grown Cousins but it was decreed from above that Jack Tatlow, Riley’s general manager, would instead fill his shoes. In the event this worked well both ways and the Coventry man was soon accepted into the Abingdon fold.

Whilst the Riley range at that time consisted of four cars, the 1½ litre and 2½ litre saloons, the Roadster and the Drophead Coupe, it was really the saloons that accounted for the bulk of Riley production. Whichever way you looked at it, it was a welcome addition to the Abingdon factory and the workforce became quite proud of their association with this well respected marque.

Although sales of the TC were holding up well in general, those to the USA were beginning to tail off. A more up to date replacement was needed to give a boost to this newly discovered but lucrative market. Cowley meanwhile had introduced a four-seater open tourer version of the Y-type known as the YT but this did little to generate any excitement. Abingdon was asked to come up with a proposal for a new two-seater. Of necessity it had to be something that could be put into production cheaply and easily. The ever resourceful Cousins came to the rescue once more. With the aid of very small team including Syd Enever and working mainly after production had finished for the day, they set about cutting five inches out of a Y-type chassis frame, making the wheelbase the same as that of the TC. Onto this they mounted a TC body tub, calling on the tinny’s shop to modify the bonnet and wings etc to make them fit. The whole thing was given a coat of paint and shipped off to Cowley for a viewing. Remarkably, the project was given management approval and the task of committing it to paper was given by Morris’s assistant chief body draughtsman, Tom Ramsey, to a young Pressed Steel trained draughtsman by the name of Jim O’Neill. Jim, who would later become MG’s chief body designer under Syd Enever, was allocated a layout table in the middle of the Morris drawing office and simply left to get on with the task. The only guidance he received was from John Thornley who would call in occasionally to see how the job was progressing. Jim’s drawings were then sent out to the Cowley experimental shop and to Bodies Branch at Coventry for the construction of a proper prototype. Jim was horrified to hear that during road testing there was so much scuttle shake that it was almost impossible to read the instruments. At this point Jim turned for help to Tom Ramsey who suggested welding a piece of sheet steel plate to both the chassis and dash panel with a cutout for the pedals. Whilst this cured the problem it was never going to be a production solution and in the event a compromise was arrived at which involved welding a tubular steel hoop or ‘goalpost’ to the chassis to reinforce the scuttle.

In July 1949 Gerald Palmer returned to Cowley from Jowett Cars Ltd (where he had been their Chief Engineer since 1942 and had designed the successful Jowett Javelin), to take over responsibility for MG and Riley design within the Nuffield Group (he would later add Wolseley to his portfolio). Jim O’Neill was one of the first to join this new department and would soon find himself immersed in the design of a brand new MG saloon.

To be continued ….

Our thanks once again to Andy Knott, Editor Safety Fast, and author, Peter Neal, for their permission to reprint this art