MG Abingdon – New Horizons Part 1

Work was already well underway on a replacement for the MGA. Experimental number EX205 had been allocated for the new model and work began in earnest in late Spring of 1957.

Work was already well underway on a replacement for the MGA. Experimental number EX205 had been allocated for the new model and work began in earnest in late Spring of 1957.

Syd Enever’s body design team were busy fleshing out his thoughts and ideas and committing them to paper, in an attempt to produce a worthy successor to the highly successful MGA. At this stage the plan was to simply have a new body shell whilst keeping the MGA’s sturdy chassis frame and running gear. Syd and John Thornley had, in fact, spent some considerable time already discussing a new model with BMCs top management at Longbridge. Deputy Chairman, George Harriman, was anxious to incorporate some of the quite exciting body designs coming out of Italy at this time into the BMC range.

To this end he contracted one of the lesser known design houses, Frua, to produce a prototype MG two-seater convertible body on a standard MGA chassis. The completed car was shipped to Abingdon where it earned many admiring glances, but an in depth appraisal showed that it would be too expensive to produce in Abingdon’s relatively small numbers.

Still working under EX205 Syd had his designers looking at a possible compromise proposal of perhaps grafting an ‘Abingdon’ grille onto the Frua body lines. Although this idea was not adopted it was just one more step along the way to a final solution. At the same time there were other proposals for a cheaper approach, by simply facelifting the existing MGA. The main thrust here was to provide a larger luggage boot and perhaps some changes to the front end to accommodate a bigger (six cylinder?) engine. The chassis team, meanwhile, were looking at the provision of a system of independent rear suspension, utilising coil springs and radius arms.

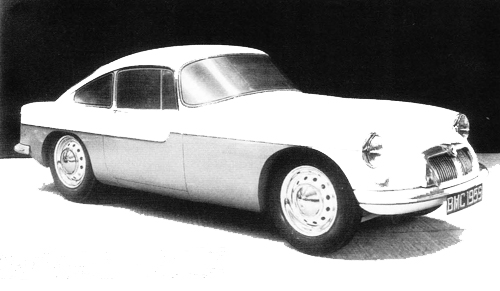

A number of ¼ scale models were made in the development shop by Harry Herring, until Syd felt he’d honed the design sufficiently to go ahead with a full size mockup. Unfortunately it had been decided to build it as a fastback 2+2 closed coupe rather than an open two-seater and its subsequent rather heavy appearance did it no favours. It just did not look exciting enough for a new MG sports car and it was therefore, literally a case of ‘back to the drawing board’.

At this juncture a new experimental number, EX214, was raised and a fresh approach was taken by the team. John Thornley’s 2+2 GT idea was quietly dropped and the decision taken to reduce the wheelbase from 94 to 91 inches. The 94in wheelbase, incidentally, dated back to the original T-type of 1936, so taking three inches out of it must have seemed a pretty radical step to take. At the same time the decision was taken to reduce the wheel size from 15 to 14 which would give the car better proportions. The wrap around windscreen was also dispensed with at this point. More models were made and EX214 gradually began to take on more of the appearance of the car that we have come to know and love as the MGB.

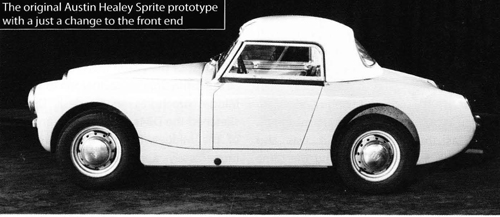

At the same time as keeping an eye on the EX214 programme, Jim O’Neill now had two other projects on his plate. The first was to design a two-seater sports version of Alec Issigonnis’s new mini car (known in-house at that time as the ‘Sputnik’). The other was to assist in productionising the new front end that had been designed for the Sprite by the Healey Motor Company at Warwick. BMC project number AD041 had been released in October 1959 for this work, which meant that all the necessary funding was in place. Four months later, project number AD047 would be issued to create an MG Midget version of the same car. The plan was to have a completely new rear end on the MG version to include a fully opening boot lid, therefore placing the Midget a little more upmarket which would be reflected in the price. When Healeys got wind of this however, they insisted that the Sprite should include this feature too!

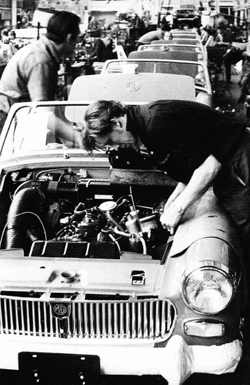

Meanwhile, elsewhere in the factory, production figures were exceeding all expectations. Consider for a moment output achieved in 1959. Calendar year figures show that a total of 44,036 had been produced not including the ‘big’ Healey. Although only financial year figures are available for these latter cars (which of course straddle a two year period), approximately 7,000 units can be added to the total, which then rises to around 50,000 cars. Compare this to the figure of 10,430 cars built just ten years earlier, and they thought that was good! What is remarkable is that this massive increase in production was achieved with hardly any increase at all in production space! What is equally remarkable is that every car, as soon as it came off the line, would be immediately road tested on the local roads. The route led out of the main (Marcham Road) gate, towards Marcham on the A415, then a right turn into Barrow Lane. Skirting the airfield the route the led on through the hamlet of Gozzard’s Ford (past the ‘Black Horse’ pub) and up to Sheepstead crossroads. Pausing only to make notes, the drivers would then make a 360 degree turn and take the same route back to the factory where the test card would be filled out. The car would then be passed off as OK or sent on to the rectification department located in ‘B’ block. This route is largely unchanged to this day.

An updated version of the MGA was announced in May 1959. To become known as the MGA1600, its ‘B’ series engine had been increased in capacity to 1588cc, bringing it into line with the Twin Cam, whilst the car was now fitted with Lockheed disc brakes on the front wheels. The car would now not only offer a better engine performance (79.5bhp @ 5600rpm), but gave improved braking performance into the bargain.

By June 1959, BMC project number AD023 had been allocated to the EX214 exercise which meant that it was now a bona fide corporate project destined for production. The Pressed Steel drawing office at Swindon was entrusted with the detail design of the monocoque bodyshell whilst Morris Bodies Branch at Coventry was designated to produce the first hand built prototypes.

With all this going on it might be thought that Syd Enever’s department had enough on its plate. Nevertheless, with John Thornley’s encouragement, yet another job was shoehorned in. Ted Lund and his team from the North West Centre of the MG Car Club were planning to return to Le Mans with the same car that they campaigned the previous year. However a rule change for 1960, requiring a full depth windscreen, meant that the only way to achieve reasonable aerodynamics would be to turn the car into a closed coupe. Don Hayter, on top of his responsibilities for the MGB, was tasked with developing a fastback version of the standard MGA coupe top. This was quickly made up in aluminium alloy and riveted to the existing body shell of the 1959 car (SRX 210). Though entered by the aforementioned group, this car was still technically the property of the MG Car Company. Finally a 1762cc version of the twin cam engine was fitted, putting the car into the two litre class. Driven by Lund and his co-driver Colin Escott, the car took top honours by winning the two litre class and finishing 12th overall out of an original line up of 55 cars.

The reader may be surprised to find that the project numbers AD051 and 52 were in fact issued to Syd Enever in November 1960. These were of course the intended replacements for the big Healey and a six cylinder MG, both to be based on the new MGB bodyshell and follow the MGB seamlessly into production. As we know, the Healey version would never see the light of day and the MG version would not appear for another seven years!

May 1961 saw the introduction of the extensively reworked Mk II Sprite, followed a month later by the Mk I Midget. Both cars were now identical apart from the badges and a few bits of chrome trim. Engine performance of 46.4bhp @ 5500rpm was less than sparkling, but with a close ratio gearbox affording good acceleration and a top speed of 85mph they would prove to be popular little sports cars.

Just prior to this a further revised version of the MGA had been announced, although with only minor changes to its outward appearance. The engine, however, was quite a different story. The capacity had been increased ed to 1622cc giving 93bhp@ 5500rpm and included many detail improvements. Listed as the 1600 Mk II, it was also accompanied by a version using the same engine but using old stock Twin Cam chassis and marketed as the 1600 Mk II Deluxe.

A lull in sales in the United States in 1960 prompted Abingdon to take on the assembly of Morris Minor vans and Travellers. Initially seen as a stopgap measure, the factory would go on to build some 20,000 of these vehicles over a five year period. This created the slightly odd situation whereby you had Cowley building MGs (Farina Magnettes) and MG building Morrises!

When, in 1960, the special body had been built for SRX 210, no EX number was raised and it has to be assumed that the cost was hidden within the Twin Cam development budget. Nothing if not brave, John Thornley was about to stick his neck out once again; this time for his old friend Dick Jacobs. Whilst looking at a road test of the Aston Martin DB4 in 1961, at the same time as having one of the new Midget brochures on his desk, Dick idly sketched the DB4s roofline onto an outline of the Midget. Excited by the result he immediately approached John Thornley about the possibility of building a fastback coupe version of the Midget with which to go racing. Thornley passed the proposal to Syd Enever who got Jim O’Neill to make a simple ¼ scale drawing which he sent to Dick Jacobs for comment. Apart from the new rootline, Jim had also rounded off the nose to give better airflow over the car.

Dick gave it the thumbs up and the job was then passed to Eric Carter at Bodies Branch to make a full size working drawing from which a prototype could be made. Wooden formers were then made up in the experimental shop and the Midland Sheet Metal Co. was entrusted with the manufacture of the new panels. The upper aluminium body structure was then fixed to a more or less standard Midget floorpan by means of rivets and epoxy adhesive. The three body shells (two for Dick Jacobs and one for John Milne in Scotland) were then shipped to Abingdon where all the mechanical and electrical components were fitted by Syd Enever’s development department.

The Jacobs cars were raced for three full seasons in both national and international events, with many class wins etc to their credit, before being returned to the factory where they became the responsibility of the BMC Competitions Department. Incidentally, these cars were always referred to as the Jacobs Midgets: perhaps as a means of concealing their true identity! These Midgets are an example of the fact that the factory had never lost their appetite for racing – even if they did have to do it in a rather clandestine manner!

Our thanks once again to Andy Knott, Editor Safety Fast, and author, Peter Neal, for their permission to reprint this article.

Comment by: Dominique M Metreaud

Would like more on the factory and production line, including pictures