Recommended Safety & Mechanical Checks for Your MGA – Part 2

In my last article I started on an idea from a recent edition of Practical Classics, which described a series of tests and inspections that could be carried out on a vehicle before submitting for the annual state-mandated inspection. Last time I dealt with the first two topics – “Checks While You’re Driving” and “Brake Checks on Your Driveway.”

In my last article I started on an idea from a recent edition of Practical Classics, which described a series of tests and inspections that could be carried out on a vehicle before submitting for the annual state-mandated inspection. Last time I dealt with the first two topics – “Checks While You’re Driving” and “Brake Checks on Your Driveway.”

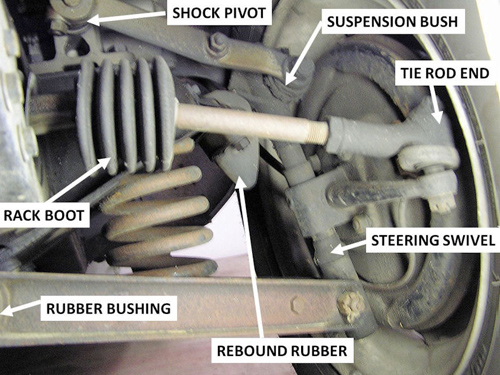

This time I present the third topic- “Steering and Suspension Checks.” Once again, I use the headers from the copiously illustrated article in Practical Classics, with the text modified to apply to the MGA. The suspension pictures are actually of my 1955 MG TF, but they show parts that are almost identical to the MGA.

STEERING & SUSPENSION CHECKS

- Steering – Sitting in the car, rock the steering wheel to check for play in the steering. Rotational play at the rim should be no more than a ó-inch. Make sure the wheel and column are securely mounted.

- Steering Joints – Check the steering and suspension with both wheels on and off the ground. Have an assistant rock the steering wheel while you feel for play in the bushes and steering joints. Listen for clunks. Possible places for “play” are the top and bottom steering swivel points (Fig. 5), and the tie rod end. On an MGA there should be no play in these locations.

- Suspension Joints – Rock the wheels top and bottom and side-to-side to check for play in the upper and lower swivel pins and knuckles (Figure 1). On an MGA, there should be no play in these locations.

- Wheel Bearings – Minor play that is the same regardless of the direction the wheel is rocked, top-to-bottom or side-to-side could be the wheel bearing. Again, on an MGA, there should be no play. Spin the wheel to check for any “grinding” sound.

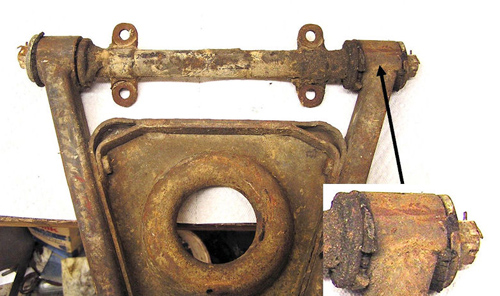

- Rubber Bushes – Suspension bushes made of rubber can crack, distort, crush, or stretch. Pry joints with a lever to check for unwanted movement. External cracks are not always an indicator of poor working condition. The only rubber bushings on an MGA front suspension are inboard of the A-arms, almost out of the picture in Figure 1. Figure 2 shows a spare A-arm (a leftover, again) on which the bushing are quite torn up and worn away.

- Boots and Gaiters – Make sure all steering, suspension, tie rod end and steering rack boots are properly attached and in good condition. The rack boot in Figure 1 is completely split open and should be replaced. There should be an intact rubber seal at the top and bottom steering swivel points, at each end of the suspension bushes and on the tie rod end.

- Shock Absorbers – Bounce on each corner of the car vigorously. When you let go, it should return to its rest position within one or two bounces. Check shock absorbers for leaks around the pivot points, and for looseness at the pivot. Check that the mounting bolts are tight.

- Coil Springs – Coil springs sometimes break near their ends. The spring seats and their surroundings are mud traps, so clean and inspect carefully for corrosion. Light rust on the springs is not a cause for concern. MGA springs sometimes break and collapse at the lower end, but this should be visible (Figure 3).

- Leaf Springs – Check for broken leaves, misalignment and loose or misshapen bushes (pry with a stout lever). Misaligned leaves may be due to bad axle alignment or collapsed eye or shackle bushes.