Fuel Leaks From MGA Carbs – How Float Bowl to Carb Assembly Can Be Confusing

A recent phone call from a fellow CCMGC member brought to my attention the potential for confusion. The member said he smelled fuel when his car was stopped, and when he opened the bonnet he could see fuel dripping from both carburetors.

A recent phone call from a fellow CCMGC member brought to my attention the potential for confusion. The member said he smelled fuel when his car was stopped, and when he opened the bonnet he could see fuel dripping from both carburetors.

I immediately knew what his problem was, and told him it was OK to drive his car to my garage, as the fuel would not be dripping while he was driving.

When he arrived, and the car had cooled down a little, I gave him the correct size socket (9/16” or 14mm), and told him to remove the bolt holding the float bowl to the carb body. I suspected that the rubber grommets (2 per carb) had hardened. In fact, they were in good condition as he has only had the car for about one year, and it was rebuilt shortly before he purchased it.

What we did find was that the arrangement around the rubber grommets was incorrect. His assembly sequence, from the top to the bottom of the hold-up bolt on both carbs was:

- Fiber washer

- Rubber grommet

- Rubber grommet

- Steel washer

The steel washer was flat, not concave as it should be. This concave washer must be fitted with the dished side up. (I have seen them fitted upside down). We made two concave washers from his flat washers using a suitably sized socket, a suitably sized nut, and a vice, to put a dish in them. We then re-assembled the float bowls to the carb bodies, leaving off the fiber washers. The final assembly was simply:

- Rubber grommet

- Rubber grommet

- Concave steel washer

This did the trick, and there were no more leaks.

The assembly confusion arises for several reasons:

- Later cars did not have a banjo bolt, but instead had a stud screwed into the carb body.

- With the stud arrangement, there was an extra steel washer above the top grommet.

- It is not clear from the parts book, or from suppliers’ catalogs, whether these 2 steel washers were flat or concave.

- In fact the parts book I have (AKD1055), shows the banjo bolt arrangement with a fiber washer (AUC1137) in the location of the dished steel washer. Perhaps the fiber washer was replaced later with a steel dished washer for better sealing of the grommets. The Workshop Manual (AKD600) appears to show a single concave steel washer at the bottom, not a fiber washer.

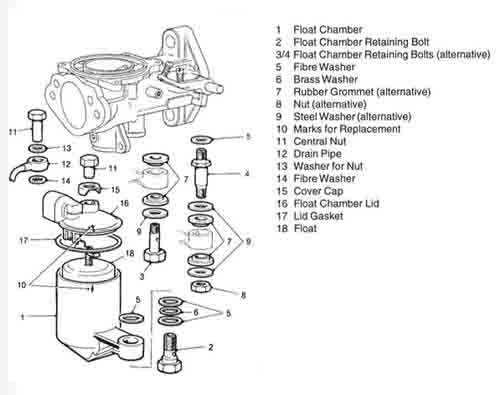

The diagram below from Burlen Fuel Systems, shows the three different arrangements.

The grommets themselves used to be rubber, but modern fuel with 5-15% ethanol content eats these rubbers in a short time. I had a new set of grommets from an SU rebuild kit last less than 2,000 miles before they started leaking. Current suppliers such as MOSS or Scarborough Faire supply grommets made of Viton® , which are supposed to be ethanol resistant (like similar fuel tank sender gaskets).

Comment by: Fred Woller

Thank god for Joe Curto, I met him 40 years ago when I had my A for 2 yrs. He helped me rebuild and tune my carbs at that time,and have never had a problem since then..I’ve only had to change the grommets 4 or 5 times in 43 years.

Comment by: George M. Kress

I did notice the washer was concave but was not sure how it went. Now I know.

Thanks

Comment by: Albert Nosenzo

Peter, I too was plagued with leaking float bowls and found that not only did I have the wrong washer but the banjo bolt was so pitted that the rubber grommets wouldn’t seal. I was able to to get new bolts and washers from Joe Curto and I’ve had no trouble since.

Comment by: Tony D Cox

Peter,

I have the later style banjo bolt or stud(alternative 4) in your diagram on my 1600 Mk2

Plagued with fuel leaks at the grommets i replaced the lower steel washers with concave washers made as you described and have not had a leak since.The inside diameter of the washer is such that it comes up at the shoulder on the bottom of the bolt restricting the compression of the grommets.Putting a slight concave shape on the washer applies enough pressure on the grommets to stop leaks..

Tony

Comment by: Blake Cowan

Thanks Peter – the problem was as you described except the previous owner rebuilt about 15 years ago but did not drive it much – in the year that I’ve had it I have more than doubled his 15 year mileage…and the fix worked perfectly. Thanks for the Church of MGA and its knowledgable members!!