MGA! Tech Talk – May/June 2017

The ignition system on our MGs is often the most neglected of areas…until the car won’t start. It tends to fall under the category of, “If it ain’t broke, don’t fix it,” which may not be the best approach in this situation. And on many occasions, when customers ask for carburetor tuning, I find the carburetors are fine. It’s the ignition system that needs tuning!

The ignition system on our MGs is often the most neglected of areas…until the car won’t start. It tends to fall under the category of, “If it ain’t broke, don’t fix it,” which may not be the best approach in this situation. And on many occasions, when customers ask for carburetor tuning, I find the carburetors are fine. It’s the ignition system that needs tuning!

One item that is often overlooked, but very important to a proper ignition system is the centrifugal advance. This controls spark timing over the entire rpm range of the engine, and is probably more important than the vacuum advance. Periodic inspection is important, although usually ignored by those who are running electronic ignition and never have reason to look inside of the distributor.

To check, simply unclip the distributor cap and remove it to reveal the ignition rotor. Give a modest twist on the rotor in the counterclockwise direction. The rotor should rotate about 20 degrees, under spring tension. Upon releasing it, the rotor should spring back to its home position. If all seems okay, this is still a good opportunity to lubricate the advance mechanism. Lift off the ignition rotor and you will see the head of a screw within the center of the distributor shaft, possibly hidden by a small felt piece. Just add a drop or two of engine oil for lubrication purposes. And if the ignition rotor didn’t move it at all during your test, or it didn’t want to return, the centrifugal action is seized or the springs are in need of replacement. The distributor should be removed for repair. If left alone, your car will be very sluggish and subject to running even hotter than normal!

Electrically speaking, there are two facets to the ignition system. One is the low-tension side, also referred to as the primary circuit, which deals with 12 volt current flowing from the ignition switch to the coil, distributor, condenser, and points. This side of the system depends on clean, solid connections, a solid 12 volt supply, and properly adjusted breaker points (or properly installed electronic conversion). The other system is the high tension side, or secondary circuit, which includes high voltage that passes from the coil to the spark plugs. This high voltage can be in excess of 20,000 volts! So it’s up to the spark plug wires, distributor cap, rotor, and spark plugs to all do their job to contain and carry this amount of voltage without fail.

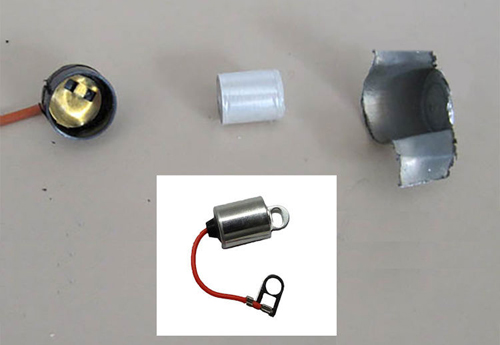

One item of recent concern in the primary circuit is an increased number of condenser failures. The condenser acts as a sponge for the surge of current when the points open, preventing pitting of the points due to a large spark. When condensers fail, they can be very difficult to diagnose. Sometimes the engine is hard to start, while in other cases, it starts and idles fine, but runs poorly under load. These symptoms usually lead mechanics in search of fuel delivery problems, faulty coils, plug wires, and even timing issues! Testing for a bad condenser is relatively simple, but not always foolproof. The condenser may actually have an intermittent issue. A clue may be indicated by a considerable amount of pitting on the points, or observing a large yellow spark between the points when cranking the engine over (vs. a small blue spark). A more accurate test involves an analog (swinging needle type) test meter. Although, this still may not reveal an intermittent problem.

Cutting the condenser open will often reveal the cause, which is usually a bad connection between two surface contacts inside the case. But now, of course, the condenser is ruined for sure! So, that was a long way around of saying, “Just replace your condenser often and carry a spare!”

On the high tension, or secondary circuit, improper spark plug wires are another issue I often see. Obviously, they need to be well insulated and have proper connections at each end. But there are some very important internal aspects that need to be considered as well.

Originally, the plug wires were of a solid core design. This is a bit confusing, as the core is actually made up of multi strands of wire… but still referred to as a solid core. These wires were almost infallible, provided the outer insulation remained intact. The downfall of solid core wires began as electronics were introduced. For the MGA, it was simply the optional radio. But even this presented a problem as the radios were known to buzz and crackle. It was determined that the noise in the radio was a result of interference from the secondary circuit of the ignition system. A simple way to reduce this crackling was to add resistance to the secondary wiring. But sometimes, resistance is futile. “Famous Dave” McCann elaborates on this:

Why add resistance to your spark circuits?

A spark ignition system is designed to charge an inductor and then send that energy out a secondary coil at a high voltage to bridge a spark gap. The spark circuit waveform looks like a very steep spike up to around 30-60KV and then a slightly less steep drop back to zero. Any such intermittent conductance is an alternating current (in this case it alternates between conducting and not conducting) and any alternating current generates electro magnetic waves. Spike type alternating current generates a wide range of frequencies of electromagnetic waves, with the magnitude of the highest frequency determined by the slope of the spike. The steeper the slope, the higher the frequency generated.

So why do we care?

Because some high frequency electromagnetic waves are also known as radio waves, and the electromagnetic waves generated are known as radio frequency interference or RFI. When our British sports cars were designed, about the only part of the car that was electronic was the radio. Even then though, the RFI could be heard on the AM radio, usually as a clicking or buzzing with a frequency proportional to the engine RPM. What was the solution to this RFI? A small amount of resistance in the spark circuits that reduced the slope of the spike enough to reduce the maximum electromagnetic wave frequency to below that of the lowest AM radio frequency.

Why is this more of an issue now?

Because now there are almost certainly more things on your car that are electronic. You might even have electronics in your ignition circuitry, and the spark RFI might interfere with the components that are responsible for the spark. Another significant recipient of RFI is GPS receivers. GPS signals are very low power, so it does not take much interference to drown them out.

Resistance in the plugs vs. resistance in the wires?

So how do you add resistance? Initially resistance was established by adding small resistors to the plug wire ends. However today, the two easiest methods are resistor plugs and resistor wires. Is there any advantage to either? No, in this case resistance is resistance.

Can I just use modern resistor plug wires with my original style cap and plug wire ends?

Modern resistor wires work very well…in modern cars. The resistance is obtained using a carbon core, which offers excellent conductivity while offering the proper resistance. Unfortunately, resistor wires are not physically compatible with the original MGA side entry distributor caps. These caps depend on a setscrew to puncture the wire and hold it in place. With a modern wire, the inner core is made up of carbon and there is nothing solid for the set screw to bite into. The same applies to the coil wire, if using an original style screw retainer system. These wires were not designed to attach in this manner, but instead use a crimp attachment. So the crimp not only attaches to the wire conductor over a wide area, but also physically holds the wire insulation over a wide area. You can use resistor plug wire fitted with compatible plug wire ends, but you will need to use an MGB top entry (points style) cap and later style coil.

Thanks Dave! Following up on Dave’s explanation of using carbon core resistor wires on the original cap and coil, if there is not a positive connection, the high voltage current will be forced to jump between the plug wire and the set screw. The jump may be very small at first, but as time passes, the spark will erode the carbon core, resulting in an ever increasing distance the spark has to jump. Eventually, the spark will find an easier path to ground, and the engine will develop a miss, or if it is the coil wire, the car may not run at all. The main thing to remember, is that the original design parts are still available, work very well for our cars, and are of the resistor type, when fitted with the resistor tips. Many of our suppliers offer complete original-style spark plug wire kits. Modernizing can be good too, but there are always implications that need to be considered. It is with the generous help of NAMGAR and other resources, such as Barney Gaylord’s mgaguru.com website, the MG Experience site, and our fantastic parts suppliers and restorations shops that continue to help us refine our MGs into safer and more reliable cars. And they deserve our highest frequency of thanks!

Comment by: Gilbert Clark DuPre, Jr

Wouldnt the electronic ignitor get rid of the rfi problem.

Comment by: Bruce Woodson

Thanks for the comments. Glad to be of help!

Comment by: Robert J Mills III

Apologize Bruce for getting your name wrong.

Thanks again for the info,

Bob

Comment by: Robert J Mills III

Thanks Bill-

1962 MGA was missing under load after putting in new points and condenser. After reading the above and prior to trailering the car to the mechanic, replaced the new condenser with a spare and pleased to report she is now running fine. Your article was timely and I am sure saved me a quite a few dollars as well as time.

Regards,

Bob

Comment by: Michael D Mitchell

A Big GRACIAZ to Bill Woodson, In Reading hiz Article, it made me Aware of Quite a Few Point’z that I have Overlooked, regarding the Ignition System on my “Ole Gal” (’58 ZB Magnette).

Again, GraciaZ Bill.