MGA! Tech Talk – November/December 2018

In each Issue of MGA! magazine, it is my responsibility to offer advice on how to fix something related to NAMGAR. I only wish I knew how to repair more than cars, as we all suffered a broken heart with the passing of Carol Shamonsky.

In each Issue of MGA! magazine, it is my responsibility to offer advice on how to fix something related to NAMGAR. I only wish I knew how to repair more than cars, as we all suffered a broken heart with the passing of Carol Shamonsky.

She was a very special person. Carol stepped forward to become our Vice Chairman in 2011 and was my right-hand person when I was Chairman. I quickly learned that her forte was not in MG knowledge, but rather in caring for people. Carol insisted that NAMGAR be about people first, a vision she carried forth as she went on to become Chairman in 2015. I know that NAMGAR is a better club because of Carol Shamonsky. I also know that I will miss her smiles, her hugs … And her friendship.

Last time, we discussed the age-old topic of overheating and the many variables that can cause this common condition. We also discussed many reasons for a relatively high operating temperature. But we also learned that there is no exact number that fits all occasions. For the purposes of this and subsequent coolant related articles, I have chosen 180 degrees Fahrenheit as a good target number. This gives sufficient heat for a smooth and reliable engine, with some overhead for hot days, slow traffic, and long hill climbs. If you desire a different number, the same principles should apply.

The first step in achieving a desired engine temperature is to know that your temperature gauge is accurate, or at least to determine how far off it is. The original MGA “dual gauge” is a very reliable unit. Both the oil and temperature segments operate on pressure. The oil side uses actual engine oil to transmit pressure to the gauge, while the temperature side uses a self-contained amount of ether that expands when heated, sending pressure through a hollow tube surrounded by a protective spiral wire all the way to the temperature gauge. A bulb is where the ether is stored. This bulb acts as a transmitter when fitted inside the cylinder head (thermostat housing on Twin Cam models) and is submerged in coolant. If the hollow tube is compromised, ether will escape, and the temperature gauge will no longer work.

The Magnette uses a similar but more sophisticated system to transmit coolant temperature to its electric gauge. The Magnette temperature transmitter is based on a bimetallic strip, similar to a mechanical turn signal flasher. When the coolant is cold, there is little resistance in the transmitter, so the gauge reads cold. As the engine warms up, the bimetallic strip expands and bends, causing a momentary open circuit. This allows the needle in the gauge to drift back towards hot. The more heat, the longer the strip is open and the closer to hot the gauge reads. (I never said the British made things the simple way).

To properly test either style temperature gauge for accuracy, I offer two approaches. The first is old-school, but gives the most accurate conclusion. Carefully remove the transmitter from the engine (no need to remove the entire gauge from the car). Please do this when the engine is cold, and pressure is relieved from the system. You will need to drain off about a gallon of coolant, or if you’re lucky enough to have an old gauge or an MGB temperature transmitter, you can quickly swap that to prevent coolant loss while you run your test. Should you run into difficulty in removing the retaining nut or the transmitter bulb itself, I recommend leaving it in place and trying the infrared test as explained later in this article.

Heat a pan of water to boiling. Borrow a quality cooking thermometer from your kitchen when no one is looking and insert into the hot water. The thermometer should read 212F just as the water boils. Carefully transport the hot water (and thermometer) to your car and insert the transmitter end into the hot water. Give the gauge a moment to stabilize and compare the temperature reading to that of your test thermometer. As the hot water cools, make several observations. If you are measuring the electric gauge of a Magnette, you will need to run a jumper lead from the body of the transmitter to a good ground source on the car and turn the ignition switch to the on position. With a good baseline established, you can now make the decision to have your gauge repaired or replaced, or hopefully that your gauge is accurate! Mark Barnhart wrote in to suggest that you should always verify a new or rebuilt gauge is accurate before installing!

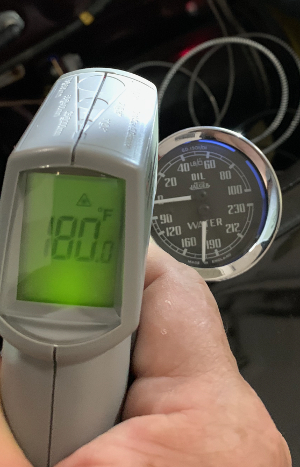

Steven Mazurek also wrote in suggesting that an infrared thermometer is a great way to verify engine temperature. As he suggests, an infrared thermometer works well to sample the temperature directly on the surface of the engine as well as radiator and other components.

But the reading you see at the temperature probe may not be a completely accurate indication of what the water temperature is at the transmitter due to variations in emissivity. Emissivity is the ratio of the radiant energy emitted by a surface to that emitted by a blackbody at the same temperature. Simply translated, it means that different materials, rough or polished surfaces, and even paint color will affect a true reading. Thus, your readings may be close, but not absolute.

But the reading you see at the temperature probe may not be a completely accurate indication of what the water temperature is at the transmitter due to variations in emissivity. Emissivity is the ratio of the radiant energy emitted by a surface to that emitted by a blackbody at the same temperature. Simply translated, it means that different materials, rough or polished surfaces, and even paint color will affect a true reading. Thus, your readings may be close, but not absolute.

Recently our shop encountered an MGA 1600 with a major overheating condition. Additionally, the temperature gauge was not working. Thus, we monitored the temperature with an infrared thermometer. From a cold start, the temperature reading at the sender location steadily rose to 190 degrees. But we could hear the coolant actually boil, and steam erupted from the overflow pipe. Of course, we suspected a faulty thermostat, but it tested perfectly in a hot water test. Once again, from a cold start, we monitored the block, cylinder head, radiator, and hoses with the infrared thermometer. As expected, the radiator remained cold while the thermostat was closed. Temperature in the in the block slowly rose to about 160 degrees. We noted the cylinder head temperature rose higher, to about 180-190 degrees. But there was a noticeable spike at the highest point of the engine, in the thermostat area. Even as the temperature passed the point in which the thermostat should have opened, the infrared indicated hot coolant did not pass on to the radiator. Just as the temperature spiked to 212 degrees, a sudden increase in temperature was indicated in the top of the radiator. But the hot coolant never circulated through the entire radiator.

Without the infrared, we might have suspected a blocked radiator. But the clues pointed to a faulty water pump. Indeed, upon removal of the pump, we found a broken impeller.

While this is an unusual problem, it is possible that impellers can corrode, slip on the shaft, or just disintegrate. This will definitely leave you steaming on the side of the road. Simple replacement of the pump will cure this important aspect of maintaining a desired engine temperature. The original pumps were a cast iron body, while most all replacements are aluminum. I see no real advantage to either, especially once painted engine color.

A handheld infrared thermometer made this diagnosis easy. It’s a great item to add to your tool box, and quality units are reasonably priced. In addition to monitoring engine conditions, an infrared is useful in checking other working parts on your MG, such as wheel temperatures, exhaust temperatures, and even hot spots in wiring!