Speedometer Calibration

VOL 17/NUMBER 3

In his letter, George Smith also asked about the serial number on the face of the speedometer and its relationship to the gearing of the car. I checked with John Twist who I knew had been trying to compile some data on the subject, but John informed me that so far he has been unable to establish any meaningful correlations. Unfortunately, the factory MGA parts list uses their own part numbers for the instruments, with no cross-reference to the Jaeger number.

In his letter, George Smith also asked about the serial number on the face of the speedometer and its relationship to the gearing of the car. I checked with John Twist who I knew had been trying to compile some data on the subject, but John informed me that so far he has been unable to establish any meaningful correlations. Unfortunately, the factory MGA parts list uses their own part numbers for the instruments, with no cross-reference to the Jaeger number.

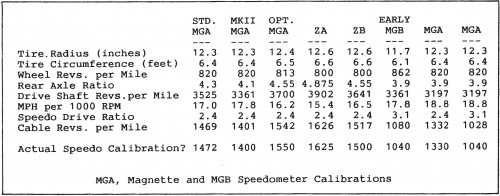

However, there is one number on the speedometer face that does have some meaning, and that is a four digit number that generally accompanies the serial number. This four digit number indicates the speedometer calibration, and is the number of revolutions of the speedometer cable for an indicated one mile of travel on the odometer. This also relates to the calibration of the speed indicating needle. To find out what numbers were appropriate to the MGA, I decided to do a little research to come up with the accompanying table. However, the results are not as conclusive as I had hoped, probably because a critical variable is the rolling radius of the tire, a value that will depend on the tire size and profile.

As a starting point, I decided to use some “known” data related to my own MGA 1500, such as rear end ratio (4.3:1), speedometer drive ratio (2.4:1) and the 4-digit number on the speedometer (1550). I also roughly measured the tire radius at about 12.3 inches. With this information, and other little known facts such as the value of pi and the number of feet in a mile, I started with the tire diameter and worked forward as follows:

Tire Radius = 12.3 inches

Tire Circumference = (6.284 x 12.3)/12 = 6.44 feet

Wheel revolutions/mile =5280/6.44 = 820

Drive Shaft revs/mile = 82O x 4.3 = 3526

Speedo cable revs/mile = 3526/2.4 =1496

This value was far from close to the 1550 on the speedometer face, and could not be accounted for by any error in my measurement of the tire radius. I had hoped to check my calculations from a quoted value for miles per hour in top gear for 1000 revolutions per minute of engine speed. Unfortunately, the MGA shop manual does not provide this value, but I did manage to find a value of 17 mph in a contemporary road from Road & Track. Since the top gear ratio for the MGA is 1:1, I could now calculate:

Speedo cable revs/mile = (l00O x 60/17)/2.4 = 1470

Which is pretty close to my previous calculation, and indicates that my tire radius measurement was close to the correct value. It was at this point that I remembered that when first I bought my MGA it had a 4.55:1 rear end in it, and the engine was pretty beat from running at high RPM. Using the 4.55:1 value for the rear end ratio in my calculations yielded a 1554 value for speedometer cable revolutions per mile, which was much closer to the 1550 value I was looking for. So, I concluded that my MGA must have been delivered from the factory with the optional 4.55:1 rear end and optional matching 1550 speedometer.

So, with that information, I concluded that I was working with the correct parameter values for the MGA, and I calculated the speedometer calibration value for the standard (1500 and 1600) MGA with the 4.3:1 rear end, and the MK II MGA with the 4.1:1 rear end. I called John Twist to see if he could verify these values, and he said that he thought that 1472 and 1400 were the correct values. These calibration values also correlated with the Road & Track road speed values of 17.0 and 17.8 miles per hour per 1000 engine RPM for the MGA, and MGA MK II, respectively. Incidentally, John also said that he had on the shelf MGA-type speedometers with calibration values of 1000, 1020, 1040, 1060, 1280, 1376, 1440 and 1450. So there are quite a variety out there to take care of different combinations of tire size and rear end ratio. The values in the 1000s are for the early MGB.

I had a couple of Z-type Magnette odometers in the attic, one with a 1625 calibration value and the other 1500, so I decided to plug these values into my calculations. The Z-type Magnette used a 4.875:1 rear end ratio in the early, mostly ZA models, and a 4.55:1 rear end ratio in the later, mostly ZB models. The Magnette also uses the same transmission as the MGA, with the 2.4: 1 speedometer drive reduction. The two Magnette calibration values checked out if I assumed a 12.6 inch tire radius, as shown in the table. This assumption is not unreasonable, because the Magnette used a slightly larger and higher profile tire than the MGA.

Just for kicks, I also calculated the speedometer calibration value for the early MGB, using 17.8 mph per 1000 RPM, 3.9:1 rear end ratio, and 3.1:1 speedometer drive reduction ratio, all of which were quoted in the MGB shop manual. This calculation required a tire size of 11.7 inches, which is not unreasonable for the MGB 14-inch wheels, but resulted in a speedometer calibration value of 1080. I settled for an actual value of 1040 because I found a speedometer with this number in the attic, but John Twist’s list indicates that a 1060 calibration is also available.

Finally, in the last two columns of the table, I calculated the effect of an MGB 3.9:1 rear end ratio in the MGA. The next to last column shows that, for the standard 2.4:1 speedometer drive reduction, a speedometer with a calibration value of about 1330 is required. I don’t know if such an animal exists! In the last column, since I intend to put a 3.9:1 rear end in my MGA, I decided to see what effect the use of the MGB speed drive reduction of 3.1:1 would have on the required MGA speedometer calibration. To my surprise, it was pretty close to the 1040 that I happen to have in the attic. I don’t know if the MGB speed reduction drive gear will fit in the MGA transmission, but I definitely intend to find out!

Well, just when I thought I had this thing all figured out, I decided to check and see what was installed in some other MGAs. I haven’t had the opportunity to check any in the local area but, while I was in the Washington, D.C., area for the MG T&A Chapters’ Christmas party, I checked the two MK lIs in Ron Eaton’s garage. They both had speeds calibrated at 1376, which blew a big hole in my calculations. I also checked an MGA 1600 and came up with a 1440 speedo, which also did not agree with my calculations. For both of these values to be correct requires a tire radius of 12.5 inches, slightly larger than the 12.3 inches I had determined. However, that tire size then does not agree with the mph per 1000 RPM quoted in Road & Track. So now I am totally confused and will stay with the values in the table while I do some more research on the subject.

So, as part of George Smith’s original question, what does all this mean to the MGA owner who wants to change tire size or rear end ratio, and still have a correctly calibrated speedometer? I would make the changes to the car first, and then take the car out on the nearest interstate highway to check the existing speedometer against the mile markers at the side of the road (or use a GPS). The odometer is the thing to check because, unlike the speed needle, that calibration does not change as the instrument ages. Drive for ten actual miles as indicated by the interstate mile markers and compare that with the miles indicated by the trip odometer to the nearest tenth of a mile. Divide the indicated odometer miles by ten (miles) to obtain the required correction factor. If the correction factor is greater than one, then the speedometer (odometer) is reading high. A high reading is caused by the cable making too many revolutions per mile for the installed instrument, and a speedometer with a higher calibration number is required. Conversely, if the correction factor is less than one, then the speedometer is reading low, and a speedometer with a lower calibration number is required.

As an example, I know from previous measurements that the odometer in my MGA is reading low by about 5%. (That should have been a clue that the speedometer did not match the rear end ratio). So, for ten actual miles of travel, my odometer would show about 9.5 miles, which results in a correction factor of 0.95. Therefore, since the installed speedometer has a calibration number of 1150, the correct speedometer would have a calibration number of 1550 x 0.95, or 1472. Which just happens to be the number I have in the table for a 4:3:1 rear end.

The speed indication for the instrument can be similarly checked. Drive on a relatively quiet piece of interstate highway (if you can find one), and maintain a constant indicated 60mph for five miles. If your speedometer is accurate, and you did not significantly vary the speed, this should take exactly five minutes. If it took more, then the speedometer is reading low, less and it is reading high. In the case of my MGA with the 5% low error in the odometer, I would expect the speed to read 5% low also and that the five miles at an indicated 60 mph would take 5 minutes and 15 second. However, since this is an error of only 3mph at 60 mph, I could live with it!

So, what should you do about your speedometer if you change the rear end ratio? I see four options in ascending order of difficulty:

- Live with the existing speedometer, with a mental note of the error as obtained for the interstate highway tests;

- Find an MGA speedometer with a closer calibration value on the face;

- Have your speedometer recalibrated;

- Use a “reduction” drive gearbox in the cable.

My preference is probably the first option. I have done many thousands of miles in my MG TF with about a 10% low error since changing from the standard 4.875:1 rear end ratio to the MGA 4:3:1 ratio. I even had a 3:9:1 ratio in there at one time, but that was a little too low for around town use! While driving, I mentally make the necessary corrections for indicated speed.

If the opportunity arises for the MGA and I happen to find a more closely calibrated instrument, I would go for the second option to try to reduce the mentally adjusted error. Unfortunately, I do not have this option for the TF because that instrument was only available in one calibration, and any optional rear end ratios were accommodated with different speedometer drive gears in the transmission.

I believe the third option is available from some of the instrument rebuilding services. I understand that Nisonger in New York used to do this at one time, but I don’t know if they still do. Their current telephone number is (914) 381-1952.

The fourth alternative is a Stewart-Warner speedometer reduction gear to achieve a cable revolution rate to match your speedometer. However, I understand that the S-W gear units do not match the MGA cable ends, but that custom cables could be made up with the reduction gear in the middle. I don’t have a source for this service or the S-W gear units, but your local parts store or speed shop may be able to help. The reduction gear can be used either way around to increase or decrease the cable revolution rate.

Comment by: Michael J Anderson

At one point US regulations required that speedometers have no more than +0%/-10% error. This was certainly the case in the late 60’s but I don’t know when it was instigated. That could well account for the error to the “fast” side you have found.

I wish I could provide a citation, but I cannot recall where it was corroborated. I initially saw reference to it in my Bentley manual for the VW Type II… Apparently German engineers decided to nail the “-10%” mark and had a spec in the manual.